Understanding the Importance of Surface Mount Technology in Electronics Manufacturing

By:Admin

In today's fast-paced world, electronic devices have become an integral part of our daily lives. From smartphones to smart home devices, the demand for smaller, more powerful, and efficient electronics is constantly on the rise. This has led to the advancement of manufacturing processes, and one technology that is leading the way in this regard is Surface Mount Technology (SMT).

SMT, also known as SMD (Surface Mount Device) technology, has revolutionized the way electronic components are mounted onto circuit boards. This technology has made it possible to create smaller, lighter, and more reliable electronic devices by eliminating the need for bulky through-hole components. SMT has also improved the efficiency of the manufacturing process, resulting in higher productivity and lower production costs.

One company that has been at the forefront of the SMT revolution is {}. Founded in {}, the company has been a pioneer in the development and implementation of SMT technology in electronic manufacturing. With a strong focus on innovation and product quality, the company has established itself as a leader in the SMT industry.

{} offers a wide range of SMT solutions, including SMT pick and place machines, soldering equipment, and inspection systems. These machines are designed to meet the needs of modern electronic manufacturing, providing high precision and speed to ensure the production of high-quality electronic products. With a commitment to continuous improvement, the company regularly introduces new and advanced SMT solutions to meet the evolving demands of the industry.

The company's SMT pick and place machines are equipped with state-of-the-art technology, allowing for the accurate and efficient placement of electronic components onto circuit boards. These machines are capable of handling a wide variety of components, from small passive devices to large integrated circuits, and can achieve high placement speeds to meet the demands of high-volume production.

In addition to pick and place machines, {} also offers advanced soldering equipment for SMT assembly. The company's soldering machines utilize cutting-edge technology to ensure precise and reliable soldering of electronic components, resulting in high-quality solder joints and robust connections. This is essential for the long-term reliability and performance of electronic devices.

Furthermore, {} provides an array of inspection systems to ensure the quality and reliability of SMT assembly. These inspection systems utilize advanced vision technology to detect defects and ensure the accuracy of component placement and solder connections. By integrating these inspection systems into the manufacturing process, {} helps its customers maintain the highest standards of quality control.

In addition to its innovative SMT solutions, {} also offers comprehensive support and services to its customers. The company provides training and technical assistance to help its customers maximize the performance and efficiency of their SMT equipment. With a global presence, {} is able to provide timely and responsive support to its customers around the world.

With its commitment to innovation, quality, and customer satisfaction, {} has earned a reputation as a trusted partner in the electronic manufacturing industry. The company's SMT solutions have been widely adopted by leading electronics manufacturers, contributing to the development of cutting-edge electronic products.

Looking ahead, {} remains dedicated to advancing SMT technology and driving the evolution of electronic manufacturing. By continuing to push the boundaries of innovation and excellence, the company is poised to play a key role in shaping the future of the electronics industry. As the demand for smaller, more powerful, and reliable electronic devices continues to grow, {}'s SMT solutions will be instrumental in meeting the industry's evolving needs.

In conclusion, SMT Surface Mount Technology has become a game-changer in the electronic manufacturing industry, and {} has been a driving force behind its advancement. With its state-of-the-art SMT solutions and unwavering commitment to customer satisfaction, the company is well-positioned to lead the way in the future of electronic manufacturing.

Company News & Blog

Discover the Latest Developments in Assembly Factory Technology

Assembly Factories to Expand Operations in Response to Increased DemandAssembly Factories, a leading manufacturer of [products], has announced plans to expand its operations in order to meet the growing demand for its products. The company, which prides itself on its commitment to quality and innovation, is poised to significantly increase its production capacity in the coming months.With a history of delivering high-quality products to customers around the world, Assembly Factories has built a strong reputation for excellence in the industry. The company's dedication to superior craftsmanship and attention to detail has earned it the trust and loyalty of a diverse customer base. As a result, demand for Assembly Factories' products has been steadily increasing, prompting the need for expansion.In response to this demand, Assembly Factories has unveiled plans to open a new state-of-the-art manufacturing facility. This facility will be equipped with the latest technology and production equipment, allowing the company to streamline its operations and increase efficiency. Additionally, the new facility will enable Assembly Factories to ramp up production and meet the growing needs of its customers."We are thrilled to announce the expansion of our operations," said [Company CEO]. "This new facility will allow us to not only meet the current demand for our products, but also position us for future growth. We are committed to maintaining the high standards of quality and innovation that our customers have come to expect from us, and this expansion will enable us to do just that."In addition to the new manufacturing facility, Assembly Factories is also planning to hire a significant number of new employees to support its expanded operations. These new hires will be tasked with various roles, including production, quality control, and logistics. The company is committed to creating new job opportunities and contributing to the local economy as it expands its operations.As part of its expansion plans, Assembly Factories is also investing in research and development to further enhance its product offerings. The company is dedicated to staying at the forefront of technological advancements in the industry, and is constantly exploring new ways to improve its products and manufacturing processes. By investing in R&D, Assembly Factories aims to continue pushing the boundaries of innovation and providing its customers with cutting-edge products.The expansion of Assembly Factories' operations is not only a testament to the company's success, but also a reflection of its commitment to meeting the needs of its customers. By increasing its production capacity and investing in new technologies, the company is positioning itself to better serve its customers and maintain its reputation as a leader in the industry."We are excited about the opportunities that lie ahead for Assembly Factories," said [Company CEO]. "The expansion of our operations represents a significant milestone for our company, and we are confident that it will allow us to continue delivering exceptional products to our customers for years to come."As Assembly Factories moves forward with its expansion plans, the company remains focused on its core values of quality, innovation, and customer satisfaction. With its new manufacturing facility, increased production capacity, and continued commitment to excellence, Assembly Factories is poised to solidify its position as a premier manufacturer of [products], and to meet the needs of its customers well into the future.

Top tips for successful PCB assembly at home

In the fast-paced world of technology, the demand for high-quality printed circuit board (PCB) assembly services continues to rise. As a leader in the industry, {} has been providing top-notch PCB assembly solutions for a wide range of applications. With a commitment to innovation and excellence, {} has established itself as a trusted partner for companies seeking reliable and efficient PCB assembly services.With the growing trend of remote work, {} has recognized the need to adapt to the changing landscape of the industry. As a result, the company has recently announced the launch of a new initiative to offer PCB assembly services for home-based workers. This initiative aims to provide individuals with the opportunity to work from home while contributing to the assembly process of high-quality PCBs.{} is well-equipped to support this initiative with its state-of-the-art facilities and advanced manufacturing capabilities. The company's team of skilled technicians and engineers are dedicated to ensuring the highest standards of quality and reliability in every PCB assembly project. By leveraging their expertise and cutting-edge technology, {} is able to meet the unique needs of home-based workers while maintaining the same level of excellence that the company is known for.One of the key advantages of this initiative is the flexibility it offers to individuals who are seeking opportunities to work from home. With {}'s support, home-based workers can now take on PCB assembly projects with ease, allowing them to maintain a healthy work-life balance while pursuing their professional goals. This initiative is also expected to open up new avenues for individuals who may have limited access to traditional employment opportunities, providing them with a chance to showcase their skills and contribute to the manufacturing industry.Additionally, this initiative aligns with {}'s commitment to sustainability and environmental responsibility. By enabling home-based workers to take on PCB assembly projects, {} is promoting a reduced need for commuting, which in turn leads to lower carbon emissions and a positive impact on the environment. This initiative reflects the company's dedication to finding innovative solutions that benefit not only its clients and employees, but also the planet as a whole.Furthermore, {}'s initiative to offer PCB assembly services for home-based workers underscores the company's ability to adapt to the evolving needs of the industry. By recognizing the growing trend of remote work and seizing the opportunity to support individuals in this space, {} continues to demonstrate its forward-thinking approach to business. This initiative not only showcases {}'s willingness to embrace change, but also positions the company as a leader in providing flexible and inclusive solutions for PCB assembly.As a reputable and reliable provider of PCB assembly services, {} is poised to make a significant impact with this new initiative. By extending its support to home-based workers, the company is creating opportunities for individuals to pursue meaningful work from the comfort of their own homes. With a strong focus on quality, innovation, and sustainability, {} remains at the forefront of the industry, setting the standard for excellence in PCB assembly services.

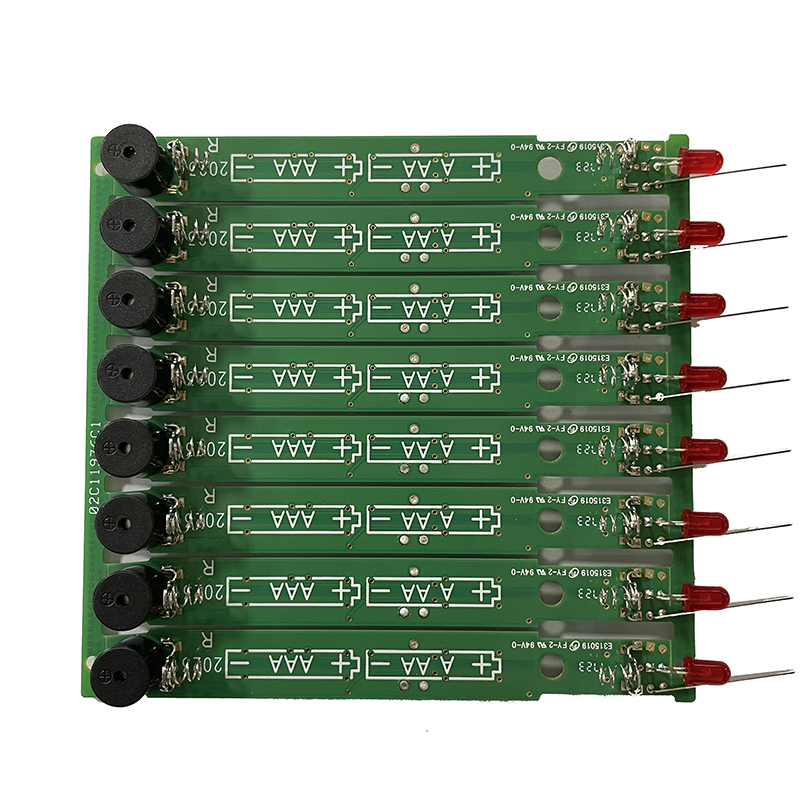

Dip Plug-In Process Factory: Streamlining the Manufacturing Process for Optimal Results

Dip Plug-In Process Factory: Revolutionizing Manufacturing InnovationIn today's fast-paced world, the constant demand for innovation and efficiency has never been higher. Industries are constantly seeking new ways to streamline their manufacturing processes and develop cutting-edge technologies. In line with this trend, a groundbreaking Plug-In Process Factory has emerged, poised to transform the industry, thanks to its revolutionary manufacturing capabilities.The newly established Dip Plug-In Process Factory aims to redefine conventional manufacturing processes by implementing state-of-the-art technologies. This cutting-edge factory is backed by an experienced team of highly skilled engineers and technicians who strive to develop innovative manufacturing solutions for various industries.Dip Plug-In Process Factory prides itself on its ability to provide end-to-end manufacturing solutions tailored to each client's specific needs. From the initial design phase to production and final assembly, this factory offers a seamless process that ensures optimal manufacturing efficiency and top-notch quality.One of the key advantages that sets Dip Plug-In Process Factory apart from its competitors is its utilization of plug-in manufacturing processes. This innovative approach allows for greater flexibility and adaptability during the production stage. With plug-in technology, manufacturers can easily modify and customize their processes to accommodate changes in product design, market demand, or unexpected challenges.By implementing plug-in manufacturing processes, Dip Plug-In Process Factory helps businesses save valuable time and resources. The ability to make quick adjustments along the production line ensures that companies can respond swiftly to market trends and customer demands, gaining a competitive edge.Moreover, Dip Plug-In Process Factory understands the importance of sustainability in today's manufacturing landscape. The factory places a strong emphasis on eco-friendly practices, integrating environmentally conscious policies into their manufacturing processes. From energy-efficient machinery to waste reduction strategies, this factory strives to minimize its environmental impact while maximizing production capabilities.Dip Plug-In Process Factory's commitment to sustainability extends beyond their manufacturing practices. They actively engage in research and development to explore cleaner and more sustainable materials for use in production. By continuously seeking innovative solutions, Dip Plug-In Process Factory aims to contribute to a greener, more sustainable future for the manufacturing industry.Furthermore, the factory also offers comprehensive training and consulting services, providing clients with the tools and knowledge necessary to optimize their manufacturing processes. By partnering with Dip Plug-In Process Factory, businesses gain access to a wealth of expertise and insights into enhancing their production capabilities.With a proven track record of successful projects across diverse industries, Dip Plug-In Process Factory has established itself as a trusted partner for businesses aspiring to revolutionize their manufacturing processes. Through their unwavering commitment to innovation, sustainability, and efficiency, this factory has become a driving force behind the transformation of the manufacturing landscape.In conclusion, Dip Plug-In Process Factory is revolutionizing the manufacturing industry through its state-of-the-art plug-in manufacturing processes. With a focus on innovation, sustainability, and customization, this factory offers end-to-end manufacturing solutions tailored to each client's needs. By embracing plug-in technology, Dip Plug-In Process Factory enables businesses to adapt quickly to market changes and streamline their production processes. With a dedicated team of experts, a commitment to sustainability, and comprehensive training and consulting services, this factory is leading the way towards a more efficient and eco-friendly future for manufacturing.

Top Tips for Medical PCB Assembly: Everything You Need to Know

Medical PCB Assembly is a crucial component of many modern medical devices. These assemblies are used in everything from patient monitoring systems and diagnostic equipment to imaging devices and life support machines. With the increasing demand for reliable and high-quality medical electronics, the importance of Medical PCB Assembly in the healthcare industry cannot be overstated.{Company Name} is a leading provider of Medical PCB Assembly solutions. With a reputation for delivering top-notch products, the company has been at the forefront of the medical electronics industry for several years. Their commitment to quality and precision has made them a trusted partner for medical device manufacturers worldwide.The company's state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to produce PCB assemblies that meet the strictest quality standards. Their team of highly skilled engineers and technicians are well-versed in the unique requirements of medical electronics, ensuring that every assembly is meticulously crafted to meet the specific needs of each device.In addition to their technical expertise, {Company Name} places a strong emphasis on compliance and regulatory requirements. They understand the importance of adhering to industry standards and regulations, and ensure that every Medical PCB Assembly they produce meets the necessary certifications and approvals.One of the key factors that sets {Company Name} apart from their competitors is their proactive approach to research and development. They continuously invest in new technologies and methodologies to improve their production processes and stay ahead of industry trends. This commitment to innovation allows them to offer their clients cutting-edge solutions that meet the evolving demands of the healthcare sector.Furthermore, the company prioritizes customer service and satisfaction, working closely with their clients throughout the entire production process. From initial design and prototyping to full-scale production and testing, they maintain open lines of communication to ensure that the final product meets the client's exact specifications.As the demand for advanced medical devices continues to grow, the need for reliable and high-quality Medical PCB Assembly solutions becomes even more critical. {Company Name} is poised to meet this demand with their unparalleled expertise, commitment to quality, and dedication to innovation. They are well-positioned to be a key player in the future of medical electronics, and their contributions to the industry are sure to have a positive impact on patient care and healthcare outcomes.The company's dedication to excellence and their track record of success make them a trusted partner for medical device manufacturers around the world. With their robust capabilities, commitment to quality, and proactive approach to innovation, {Company Name} is well-equipped to continue leading the way in Medical PCB Assembly for years to come.In conclusion, Medical PCB Assembly is a crucial component of modern medical devices, and {Company Name} is a leading provider of high-quality solutions for the healthcare industry. Their dedication to excellence, commitment to compliance, and proactive approach to innovation make them an invaluable partner for medical device manufacturers worldwide. With their continued focus on quality and customer satisfaction, {Company Name} is poised to remain at the forefront of Medical PCB Assembly for the foreseeable future.

Top Wire Bonding Factories: The Latest News and Updates

Alabama Wire Bonding Factories Expand Operations to Meet Growing DemandThe Alabama wire bonding industry is experiencing a period of rapid growth as demand for advanced electronic components continues to rise. In response to this increased demand, several wire bonding factories in the state have recently announced plans to expand their operations and invest in new technologies to stay ahead of the competition.One of the leading wire bonding companies in Alabama, [Company Name], has been at the forefront of this expansion, with plans to invest in new equipment and facilities to meet the growing needs of its customers. With a strong focus on quality and innovation, [Company Name] has become a trusted partner for many major electronics manufacturers, providing high-quality wire bonding solutions for a wide range of applications.The company's success can be attributed to its commitment to staying ahead of the curve when it comes to technology and innovation. By continuously investing in state-of-the-art equipment and upgrading its facilities, [Company Name] has been able to deliver cutting-edge wire bonding solutions that meet the most demanding requirements of its customers."We are seeing a significant increase in demand for our wire bonding services, particularly in the automotive, aerospace, and consumer electronics sectors," said [Company Name]'s CEO. "In order to meet this growing demand, we have decided to expand our operations and invest in new technologies that will enable us to continue delivering the high-quality solutions that our customers have come to expect from us."In addition to expanding its operations, [Company Name] is also focused on developing new wire bonding technologies that will further enhance the performance and reliability of its products. The company's team of engineers and technicians are constantly working on new innovations that will allow them to stay ahead of the competition and continue to meet the evolving needs of the industry.One of the key areas of focus for [Company Name] is the development of advanced bonding techniques that will enable them to create smaller and more complex wire bonds, which are essential for many modern electronic devices. By investing in cutting-edge equipment and training its workforce to use the latest technologies, the company is positioning itself as a leader in the industry and a go-to partner for customers with the most demanding requirements.The expansion and investment plans of [Company Name] are reflective of the larger trend that is taking place in the Alabama wire bonding industry. Several other companies in the state have also announced plans to expand their operations and invest in new technologies in response to the increasing demand for their products and services.This growth in the industry is not only beneficial for the companies themselves, but also for the state of Alabama as a whole. The wire bonding industry is a major contributor to the state's economy, providing high-quality jobs and driving innovation and technological advancement in the region.As the Alabama wire bonding industry continues to grow, it is clear that companies like [Company Name] will play a key role in shaping its future. By investing in new technologies and expanding their operations, these companies are ensuring that they will continue to meet the needs of their customers and remain at the forefront of the industry for years to come.

Top Contract Electronics Manufacturers in China: Key Player in the Global Market

China Contract Electronics, a leading provider of electronic manufacturing services, has recently announced a significant contract with a global technology company. The contract will see China Contract Electronics manufacturing a range of electronic products for the technology giant, further solidifying the company's position as a key player in the electronics manufacturing industry.Established in 2005, China Contract Electronics has steadily grown to become a reputable name in the contract manufacturing sector. With state-of-the-art facilities and a commitment to delivering high-quality products, the company has gained the trust and confidence of numerous clients worldwide.The recent contract with the global technology company is a testament to China Contract Electronics' capabilities and expertise in electronic manufacturing. The company's ability to provide end-to-end manufacturing solutions, from prototyping to mass production, has positioned it as a preferred partner for businesses looking to bring their electronic products to market."We are thrilled to have been chosen as the manufacturing partner for this global technology company," said the CEO of China Contract Electronics. "This contract is a testament to our unwavering commitment to excellence and our ability to meet the diverse needs of our clients. We look forward to leveraging our expertise to deliver high-quality electronic products that will meet and exceed the expectations of our client and their customers."With a focus on innovation and continuous improvement, China Contract Electronics has invested heavily in cutting-edge technology and equipment to ensure that its manufacturing capabilities are at the forefront of the industry. The company's facilities are equipped with advanced machinery for surface mount technology, through-hole assembly, testing, and inspection, allowing it to handle a wide range of electronic products with precision and efficiency.In addition to its manufacturing capabilities, China Contract Electronics places a strong emphasis on quality control and assurance. The company adheres to stringent quality standards and has earned various certifications and accreditations, including ISO 9001 and ISO 14001, demonstrating its commitment to delivering products of the highest quality while minimizing its environmental impact.Furthermore, China Contract Electronics is dedicated to providing a seamless and transparent manufacturing experience for its clients. From project management and supply chain optimization to logistics and fulfillment, the company offers comprehensive support throughout the manufacturing process, ensuring that clients can bring their products to market on time and within budget.The partnership with the global technology company is expected to propel China Contract Electronics to new heights, further strengthening its position in the electronics manufacturing industry. The contract not only signifies a significant milestone for the company but also underscores its ability to compete on a global scale.As China Contract Electronics continues to expand its client base and take on new and exciting projects, the company remains committed to upholding its core values of integrity, quality, and innovation. With a focus on building long-term partnerships, China Contract Electronics is poised to play a pivotal role in shaping the future of electronic manufacturing, delivering cutting-edge solutions that will drive the industry forward.In conclusion, the recent contract with the global technology company is a testament to China Contract Electronics' position as a leading provider of electronic manufacturing services. With its state-of-the-art facilities, unwavering commitment to quality, and dedication to innovation, the company is well-positioned to drive the future of electronic manufacturing and deliver exceptional results for its clients.

Key Developments in the Electronics Supply Chain: A Comprehensive Overview of the Industry

The electronics supply chain is a critical component of the global economy, comprising a complex network of manufacturers, suppliers, distributors, and retailers that work together to design, produce, and deliver electronic components and devices to consumers. This supply chain is vital for the production and distribution of a wide range of products, from smartphones and tablets to computers and televisions.One key player in the electronics supply chain is {}, a leading company that specializes in the production and distribution of electronic components. With a global footprint and a wide range of products and services, {} plays a crucial role in ensuring the smooth functioning of the electronics supply chain.{} has a strong reputation for reliability, quality, and innovation, and its products are used in a wide range of applications, from consumer electronics to industrial equipment. The company's extensive product portfolio includes semiconductors, passive components, connectors, and integrated circuits, among others.In addition to its product offerings, {} also provides a range of value-added services to its customers, including design support, inventory management, and logistics solutions. This enables the company to provide comprehensive support to its customers throughout the entire product lifecycle, from initial design and prototyping to mass production and distribution.One of the key strengths of {} is its global reach, with a network of manufacturing facilities, distribution centers, and sales offices located in key markets around the world. This enables the company to serve customers across multiple industries and geographies, ensuring that it can adapt to changing market conditions and customer needs.In recent years, the electronics supply chain has faced numerous challenges, including supply chain disruptions, component shortages, and geopolitical tensions that can impact the flow of materials and products. These challenges have underscored the importance of having a resilient and flexible supply chain, as well as strong partnerships with suppliers and customers.{} has responded to these challenges by investing in its supply chain capabilities, including expanding its manufacturing footprint, optimizing its logistics operations, and enhancing its relationships with key suppliers and customers. These efforts have allowed the company to better navigate market volatility and ensure a reliable supply of products to its customers.Looking ahead, the electronics supply chain is expected to continue evolving in response to changing market dynamics and technological advancements. This includes the continued growth of the Internet of Things (IoT), the development of new materials and manufacturing processes, and the increasing demand for sustainable and environmentally friendly products.As a key player in the electronics supply chain, {} is well-positioned to capitalize on these trends and drive innovation and growth in the industry. The company's strong track record, global presence, and commitment to customer satisfaction make it a trusted partner for companies seeking to navigate the complexities of the electronics supply chain.In conclusion, the electronics supply chain is a critical and dynamic component of the global economy, and companies like {} play a vital role in ensuring its smooth functioning. With its extensive product portfolio, value-added services, and global reach, {} is well-equipped to meet the evolving needs of its customers and drive innovation in the electronics supply chain.

What is a Double In-Line Package and How Does It Work?

Double In-Line Package (DIP) has long been a popular choice for electronic devices, offering a versatile and convenient packaging solution for integrated circuits, resistors, and other electronic components. The simplicity and reliability of DIP make it a preferred option for many engineers and manufacturers. The compact design and easy to use nature of DIP make it an ideal choice for a wide range of applications, from consumer electronics to industrial machinery.One company that has been at the forefront of DIP technology is {}. With a long history of innovation and expertise in electronic packaging, {} has been a leader in the development and production of high-quality DIP products. Founded in 1980, {} has built a strong reputation for delivering reliable and cost-effective packaging solutions to customers around the world. The company's commitment to quality and innovation has made it a trusted partner for many leading manufacturers in the electronics industry.{}'s extensive line of DIP products includes a wide variety of options to meet the specific needs of its customers. From standard DIP sockets to custom-designed solutions, {} offers a comprehensive range of products to support the diverse requirements of its clients. With a focus on precision engineering and stringent quality control, {} ensures that its DIP products meet the highest standards for performance and reliability.In addition to its broad product line, {} also provides a range of value-added services to support its customers throughout the entire manufacturing process. From design and prototyping to production and testing, {} works closely with its clients to deliver tailored solutions that meet their unique needs. With a team of experienced engineers and a state-of-the-art manufacturing facility, {} has the capability to handle even the most complex DIP packaging requirements with precision and efficiency.One of the key advantages of {}'s DIP products is their versatility and adaptability. Whether it's for a simple consumer electronics device or a sophisticated industrial control system, {} offers DIP solutions that can be customized to fit the specific requirements of each application. This flexibility, combined with the company's commitment to quality and customer satisfaction, has made {} a preferred choice for many electronics manufacturers and designers.As the demand for electronic devices continues to grow, the need for reliable and efficient packaging solutions like DIP will remain essential. With its longstanding expertise and dedication to innovation, {} is well-positioned to continue leading the way in the development and production of high-quality DIP products. As the industry evolves, {} remains committed to meeting the changing needs of its customers and delivering cutting-edge solutions that drive success in the electronics market.In conclusion, Double In-Line Package (DIP) remains a popular and versatile packaging solution for electronic components, and {} has been a leading provider of high-quality DIP products for over 40 years. With a focus on precision engineering, flexibility, and customer satisfaction, {} has established itself as a trusted partner for many leading electronics manufacturers and designers. As the demand for electronic devices continues to grow, {} is well-equipped to meet the evolving needs of the market and continue delivering innovative DIP solutions to its customers.

Top Box Build Suppliers: The Complete Turnkey Solution for Your Needs

In today's highly competitive market, businesses are constantly seeking ways to streamline their operations and improve efficiency. One way they are achieving this is by outsourcing their turnkey box build needs to experienced suppliers. These suppliers provide comprehensive services, from design and prototype to full-scale production, assembly, and testing.One such company that has been making waves in the industry is {}. With over 20 years of experience in the electronics manufacturing services (EMS) industry, they have established themselves as a leading turnkey box build supplier. Their state-of-the-art facilities and commitment to excellence have earned them a reputation for delivering high-quality, custom solutions to their clients.In a recent press release, {} announced their expansion into the turnkey box build market, citing increased demand from their clients for a one-stop solution for their electronic enclosure needs. The company's CEO expressed their excitement about this new venture and their confidence in their ability to deliver exceptional results.The turnkey box build services provided by {} are a game-changer for businesses looking to streamline their operations. By outsourcing the entire box build process to a trusted supplier, companies can focus on their core competencies and leave the complexities of manufacturing to the experts. This not only saves time and resources but also ensures that the final product meets the highest standards of quality and reliability.The process begins with design and prototyping, where {}'s team of experienced engineers works closely with the client to understand their specifications and requirements. Once the design is approved, the company's advanced manufacturing facilities take over, producing the enclosures with precision and efficiency. The assembly and testing phase ensures that the final product meets all performance and quality standards before it is delivered to the client.By offering turnkey box build services, {} is positioned to become a valuable partner for businesses in a wide range of industries, including aerospace, telecommunications, medical devices, and industrial equipment. Their ability to provide a complete end-to-end solution sets them apart from traditional EMS providers and gives their clients a competitive edge in the market.In addition to their technical expertise, {}'s commitment to customer service is also a driving force behind their success in the turnkey box build market. Their team is dedicated to providing personalized support at every stage of the process, ensuring that their clients' needs are met with the highest level of professionalism and attention to detail.As the demand for turnkey box build services continues to grow, {} is well-positioned to capitalize on this trend and further solidify their reputation as a trusted and reliable partner for businesses seeking top-quality electronic enclosures. With their proven track record and dedication to excellence, they are set to become a leading player in the industry.In conclusion, the expansion of {} into the turnkey box build market is a significant development that will benefit businesses seeking streamlined solutions for their electronic enclosure needs. With their extensive experience, advanced facilities, and commitment to customer satisfaction, {} is poised to make a lasting impact in this growing market.

Top-quality assembly boards for manufacturing in China: A complete guide

China Assembly Boards (CAB), a leading manufacturer of electronic assembly boards, has announced a major expansion of its operations. The company, known for its high-quality and innovative products, is set to significantly increase its production capacity in response to growing demand for electronic components.Established in 2005, CAB has quickly become a key player in the electronic manufacturing industry. The company boasts state-of-the-art facilities and a team of highly skilled engineers and technicians, enabling it to deliver cutting-edge solutions to its customers. With a focus on quality, reliability, and efficiency, CAB has built a strong reputation for excellence in the industry.The expansion of CAB’s operations comes at a time when the global demand for electronic components is on the rise. As the world becomes increasingly reliant on electronic devices and technologies, the need for high-quality assembly boards has never been greater. CAB is well-positioned to meet this demand, and the company’s expansion plans reflect its commitment to maintaining its position as a market leader.The increased production capacity will allow CAB to better serve its existing customers while also pursuing new opportunities in the market. With a diverse range of products and services, including printed circuit boards, flexible circuit boards, and rigid-flex circuit boards, the company is poised to capitalize on the growing demand for electronic components across various industries.In addition to expanding its production capacity, CAB is also investing in research and development to enhance its product offerings further. The company recognizes the importance of innovation in staying ahead of the competition and meeting the evolving needs of its customers. By leveraging the latest technological advancements and industry best practices, CAB aims to continue delivering high-quality, reliable, and cost-effective solutions to its global clientele."We are excited to announce our expansion plans, which mark a significant milestone for our company," said the spokesperson for CAB. "The increased production capacity and investment in R&D will allow us to better serve our customers and drive the next phase of growth for our business. We are committed to maintaining our position as a leading manufacturer of electronic assembly boards and meeting the needs of our customers in the ever-changing electronics industry."The expansion of CAB’s operations is expected to create new job opportunities and support the local economy. As the company ramps up its production, it will need to hire additional staff to support its increased manufacturing activities. This is welcome news for job seekers in the region and underscores CAB’s contribution to the communities in which it operates.Furthermore, the expansion will also have a positive impact on CAB’s supply chain partners and other stakeholders. As the company increases its production, it will require a greater volume of raw materials and components, creating new business opportunities for its suppliers. This ripple effect will extend to other businesses in the industry, contributing to overall economic growth and prosperity.In conclusion, the expansion of China Assembly Boards represents a significant development for the company and the electronic manufacturing industry as a whole. With its focus on quality, innovation, and customer satisfaction, CAB is well-positioned to leverage the growing demand for electronic components and maintain its leadership position in the market. The company’s commitment to expanding its operations, investing in research and development, and contributing to the local economy bodes well for its future success and continued growth.