Master the Art of Surface Mounting Soldering Techniques for Exceptional Results

By:Admin

In today's rapidly evolving world, technology plays an integral role in our daily lives. From smartphones to smart homes, the demand for advanced electronic devices continues to soar. Behind the scenes, electronic manufacturers strive to keep up with consumer expectations by constantly upgrading their manufacturing processes. One such breakthrough is surface mounting soldering, a technique that has revolutionized the industry by offering speed, precision, and efficiency.

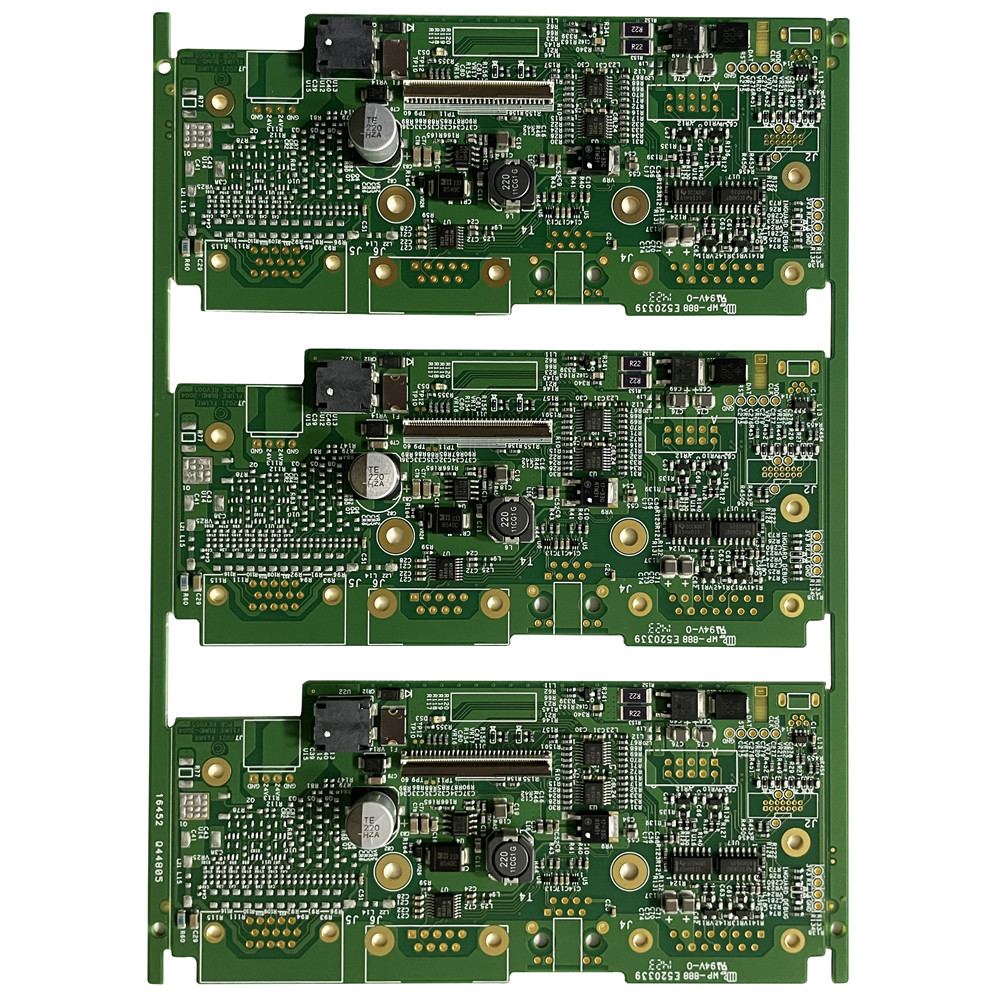

Surface mounting soldering, or SMT, is a method used to assemble electronic circuits where the components are directly mounted onto the surface of a printed circuit board (PCB). Unlike traditional through-hole soldering, which involves inserting leads through holes on the PCB, SMT eliminates the need for holes and allows for smaller, more compact devices. This technique has become increasingly popular due to its ability to meet the growing demand for smaller, smarter, and more portable electronic products.

With the rise of SMT, manufacturers can now design and produce devices that are not only aesthetically appealing but also highly-functional. By eliminating the bulky components and minimizing the space required, SMT allows for the creation of sleek and lightweight products that fit seamlessly into our increasingly connected world. From wearables to Internet of Things (IoT) devices, the applications of SMT are virtually limitless.

One of the key benefits of surface mounting soldering is its ability to improve the speed and efficiency of the manufacturing process. Traditional through-hole soldering involves manually soldering each component onto the PCB, a time-consuming and labor-intensive task. In contrast, SMT utilizes automated pick-and-place machines that can accurately place multiple components simultaneously, reducing the assembly time significantly. This results in faster production cycles, allowing manufacturers to meet consumer demands more efficiently and cost-effectively.

Furthermore, SMT offers superior precision and reliability compared to through-hole soldering. The automated machines used in SMT ensure consistent component placement, guaranteeing a higher level of accuracy. The solder joints formed in SMT also tend to be smaller and more reliable, as the surface tension distributes the molten solder evenly and creates stronger connections. This ensures the long-term reliability of the electronic devices and reduces the risk of failures or malfunctions.

In addition to its speed and precision, surface mounting soldering also promotes sustainability in electronic manufacturing. SMT allows manufacturers to minimize the amount of waste generated during the assembly process. With through-hole soldering, excess leads and wires are often cut off and discarded, leading to unnecessary material wastage. However, SMT's minimalistic design approach reduces the amount of material required and maximizes the utilization of resources, making it a greener option for the industry.

{Company intro}: As a leading innovator in the electronics manufacturing industry, our company is at the forefront of adopting SMT technology. We understand the increasing demands of consumers for smaller, faster, and smarter devices, and aim to meet those demands through the integration of surface mounting soldering into our manufacturing processes. Our state-of-the-art facilities house the latest pick-and-place machines and cutting-edge SMT equipment, enabling us to deliver high-quality products with exceptional precision and reliability.

With the advent of surface mounting soldering, the landscape of electronic manufacturing has been forever transformed. This advanced technique has not only improved the quality, performance, and aesthetics of electronic devices but has also enhanced the overall manufacturing process. By embracing the benefits of SMT, manufacturers can meet consumer demands more efficiently, reduce waste, and contribute to a more sustainable future in the industry. As technology continues to evolve, surface mounting soldering will undoubtedly remain a vital tool for innovators pushing the boundaries of what is possible in the electronic realm.

Company News & Blog

Latest Updates on China's Turnkey Box Build Services Revealed!

Title: China's Evolving Turnkey Box Build Industry Poised for GrowthIntroduction:China's turnkey box build industry has experienced tremendous growth in recent years, driven by the country's booming manufacturing sector. With a strong foundation in electronics manufacturing, China has become a global leader in providing efficient and cost-effective turnkey solutions. By harnessing its skilled labor force, advanced technology, and emphasis on high-quality outputs, the country aims to revolutionize the box build industry on a global scale.Paragraph 1:Box build refers to the complete assembly of electronic components into a finished product, ready for immediate use. This often involves the integration of printed circuit boards (PCBs), connecting cables, enclosures, and various other components. Traditionally, this process involved multiple suppliers and manufacturers working together to create a final product. However, turnkey box build solutions have emerged as a more streamlined and efficient alternative, offering end-to-end assembly and testing services.Paragraph 2:China, with its vast manufacturing capabilities, boasts numerous advantages that make it an ideal destination for turnkey box build projects. The country's extensive supply chain network ensures the availability of components at competitive prices. Additionally, strategic partnerships with component manufacturers allow for seamless integration within the assembly process. China's flexible manufacturing processes, combined with its skilled workforce, enable rapid and cost-effective production of high-quality electronic products.Paragraph 3:The increasing demand for turnkey box build solutions in various industries, such as automotive, telecommunications, consumer electronics, and healthcare, has propelled China's rise as the go-to destination for box build projects. This trend is fueled by the shifting dynamics in global supply chains, with many companies restructuring their operations to leverage China's efficient and reliable manufacturing capabilities.Paragraph 4:China has also invested heavily in research and development (R&D) activities to enhance its technological capabilities within the box build industry. Innovation centers and technology parks have been set up across the country to foster collaboration between industry leaders, manufacturers, and academic institutions. These initiatives aim to drive the adoption of advanced technologies such as automation, robotics, and artificial intelligence, further enhancing the efficiency and quality of turnkey box build processes.Paragraph 5:To ensure the highest standards and regulatory compliance, China has established stringent quality control and certification procedures. International standards such as ISO, UL, and RoHS are adhered to, ensuring that products manufactured in China meet global quality benchmarks. Additionally, the Chinese government continues to invest in training programs and certifications for its workforce to maintain the highest level of craftsmanship and expertise.Paragraph 6:China's turnkey box build industry has not been immune to the challenges posed by the global COVID-19 pandemic. However, the country's quick response in containing the virus and implementing effective safety measures has allowed the industry to quickly rebound. In fact, the pandemic has reinforced China's position as a reliable and resilient manufacturing hub, attracting companies seeking to diversify their supply chains and reduce dependency on a single region.Conclusion:China's turnkey box build industry is poised for continued growth and evolution, driven by its strong manufacturing capabilities, technological advancements, and emphasis on quality and efficiency. With the ongoing shift in global supply chains and the increased demand for reliable and streamlined assembly solutions, China remains at the forefront of the box build industry, paving the way for new opportunities and partnerships on a global scale.

China's New Energy Electronics Industry Surges Amid Growing Demand

China New Energy Electronics Set to Revolutionize the Market with Cutting-Edge Technologies China New Energy Electronics (CNEE) is poised to make a groundbreaking foray into the renewable energy market by introducing state-of-the-art technologies that will revolutionize the industry. With a vision to build a sustainable and green future, CNEE aims to spearhead the adoption of clean energy solutions on a global scale. CNEE, a leading player in the field of new energy electronics, has a diverse range of products and services under its portfolio. From solar panels and wind turbines to energy storage systems and electric vehicle (EV) charging infrastructure, CNEE is at the forefront of technological innovation in the renewable energy sector. With a strong emphasis on research and development, the company constantly pushes the boundaries of what is possible in the realm of clean energy. With environmental concerns and the need for sustainable energy becoming more prominent, CNEE's cutting-edge technologies are expected to play a crucial role in shaping the future of the industry. The company's commitment to providing efficient and reliable renewable energy solutions has been recognized by industry experts and customers alike. CNEE's solar panels employ the latest advancements in photovoltaic technology, resulting in high conversion rates and maximum energy generation. These panels are not only efficient but also aesthetically pleasing, allowing them to seamlessly blend into various architectural designs. Additionally, CNEE is actively exploring new materials and manufacturing processes to enhance the performance and durability of its solar panels. The company's wind turbines utilize advanced aerodynamic designs and intelligent control systems to optimize energy production. With an emphasis on minimizing noise and maximizing power output, CNEE's wind turbines are the pinnacle of efficiency and reliability. Furthermore, the company is actively developing offshore wind farms, harnessing the immense power of the ocean to generate clean and renewable energy. Energy storage systems are another area in which CNEE excels. The company's battery technologies offer high energy density, rapid charging capabilities, and extended cycle life. These energy storage systems can be seamlessly integrated with solar and wind power installations, effectively addressing the issue of intermittent energy production. As the demand for reliable energy storage solutions continues to grow, CNEE is well-positioned to meet the needs of the industry. CNEE is also committed to the widespread adoption of electric vehicles. The company's EV charging infrastructure provides fast and efficient charging options, making electric transportation more accessible and convenient. With a focus on intelligent charging solutions, CNEE aims to build a comprehensive network of EV charging stations to support the global transition to electric mobility. In addition to its impressive product portfolio, CNEE places great importance on sustainability and environmental stewardship. The company adheres to strict environmental standards in its manufacturing processes, ensuring minimal carbon footprint and waste generation. CNEE actively promotes recycling and reuse of materials to reduce the environmental impact associated with its products. As CNEE continues to innovate and expand its reach, the company is set to become a driving force in the renewable energy market. With a strong commitment to technological advancement and sustainability, CNEE aims to accelerate the transition to a greener and more sustainable future. By providing cutting-edge solutions in solar energy, wind power, energy storage, and EV charging, CNEE is revolutionizing the industry and cementing its position as a global leader in new energy electronics.

Exploring the Pros and Cons of Prototype PCB Board Factories

Title: Prototype PCB Board Factories Revolutionize Electronics Manufacturing IndustryIntroduction:In a rapidly evolving technology landscape, prototype PCB board factories have emerged as a crucial component of the electronics manufacturing sector. By facilitating the production of prototype printed circuit boards (PCBs), these factories are revolutionizing the industry by accelerating the product development cycle, reducing time-to-market, and bringing innovation within reach of entrepreneurs and small enterprises.The Role of Prototype PCB Board Factories:Prototype PCB board factories serve as a bridge between design and mass production. With state-of-the-art manufacturing capabilities and expertise, they transform innovative ideas into functional prototypes. Through an integrated approach that encompasses design optimization, material selection, and fast prototyping, these factories ensure the rapid realization of an idea into a physical, testable product. Simultaneously, they help identify potential design flaws, ensuring the final product is highly reliable and meets the desired specifications.The Manufacturing Process:Prototype PCB board factories employ cutting-edge technology, automated machinery, and precise quality control measures to streamline the manufacturing process. Surface-mount technology (SMT) allows for the mounting of electronic components directly onto the PCB, enhancing efficiency and minimizing manufacturing costs. Furthermore, the use of surface-mount technology enables the creation of smaller and more compact PCBs, ideal for modern electronic devices.Advanced software tools such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) enable seamless collaboration between design engineers and the factory. These tools ensure the accurate translation of design files into manufacturing instructions, guaranteeing a precise replication of the product envisioned by the designer.The Impact on Time-to-Market:Historically, developing a prototype PCB could be a lengthy and costly process, hindering innovation and delaying time-to-market. However, with the rise of prototype PCB board factories, this process has been significantly accelerated. From the initial design to manufacturing the first working PCB, the time required has been drastically reduced, allowing innovators to iterate and refine their designs rapidly. This shortened development cycle fosters innovation and enables companies to respond swiftly to market demands.Enabling Entrepreneurs and Small Enterprises:Prototype PCB board factories have leveled the playing field for entrepreneurs and small enterprises seeking to bring their innovative products to market. Traditionally, the cost associated with producing a prototype has been a significant barrier to entry for many aspiring innovators. However, the availability of affordable, high-quality prototype PCBs has empowered entrepreneurs, giving them the opportunity to transform their ideas into tangible products without having to make substantial upfront investments. This democratization of the manufacturing process has fueled the growth of start-ups and nurtured a vibrant ecosystem of innovators.Ensuring Quality and Reliability:Prototype PCB board factories prioritize the quality and reliability of the manufactured prototypes. These factories employ stringent quality control measures at every step of the manufacturing process. Automated optical inspection (AOI), X-ray inspection, and flying probe testing are just a few of the techniques employed to guarantee that the final product adheres to the highest industry standards. By conducting extensive testing and verification before the mass production phase, manufacturers can identify any potential issues, rectify them, and deliver reliable prototypes to their clients.Looking Towards the Future:The increasing demand for technologically advanced products, coupled with the emergence of disruptive technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, emphasizes the necessity for agile and efficient prototype PCB board factories. These factories are well-positioned to support the growth of industries spanning from healthcare to automotive and from smart cities to consumer electronics.In conclusion, prototype PCB board factories are playing a pivotal role in transforming the electronics manufacturing industry. By providing entrepreneurs and small enterprises with access to affordable and high-quality prototype PCBs, they are catalyzing innovation and streamlining the time-to-market. With their advanced manufacturing capabilities, seamless collaboration with designers, and commitment to quality, these factories are shaping the future of electronics manufacturing and propelling industries towards exponential growth.

Boost Your Electronics Manufacturing with High-Quality PCB Assembly Services

[Publication Name] – [Date]PCB Assembly Firm Enhances Production Capabilities to Meet Growing Demand[City, State] – With the increasing demand for advanced PCB assembly services, [PCB Assembly Firm] has expanded its production capabilities, allowing the company to better cater to the needs of its diverse clientele. As a leading provider of high-quality and reliable PCB assembly solutions, [PCB Assembly Firm] has established its position within the industry by combining cutting-edge technology, a skilled workforce, and a commitment to exceptional customer service.[PCB Assembly Firm] specializes in offering end-to-end PCB assembly services, including prototyping, component sourcing, assembly, testing, and quality control. Whether it's a small-scale project or a large-scale production run, the firm's state-of-the-art facility and experienced team ensure that each assembly meets the highest industry standards.Based in [City, State], [PCB Assembly Firm] has been serving a wide range of industries, including automotive, telecommunications, medical devices, consumer electronics, and more. The company's ability to adapt to evolving market trends and regulatory requirements has been instrumental in maintaining its strong clientele base and establishing itself as a trusted partner for businesses seeking reliable PCB assembly services.One of the primary reasons behind [PCB Assembly Firm]'s success is its continuous investment in advanced manufacturing equipment and technology. The firm recently upgraded its production facility, doubling its capacity and incorporating cutting-edge machinery. By doing so, [PCB Assembly Firm] ensures it remains at the forefront of technological advancements, guaranteeing the efficient and precise assembly of complex PCBs.The company's investment in new equipment has allowed it to meet the increased demand for high-density assemblies, incorporating smaller components while improving overall performance. As the industry continues to move towards miniaturization and improved functionality, [PCB Assembly Firm] is well-equipped to fulfill the evolving needs of its customers."We understand that our clients require not only high-quality PCB assembly services, but also timely deliveries," said [Spokesperson], the spokesperson for [PCB Assembly Firm]. "Our latest expansion enables us to maintain our commitment to quick turnaround times without compromising on quality. We take pride in our ability to fulfill our clients' assembly needs, no matter how complex."In addition to its investments in equipment, [PCB Assembly Firm] places significant importance on the expertise and skillset of its workforce. The company employs a team of highly trained technicians and engineers who are well-versed in the latest industry standards and best practices. This team is responsible for overseeing every step of the assembly process, ensuring that each product meets the stringent quality requirements expected by [PCB Assembly Firm]'s clients.Furthermore, [PCB Assembly Firm] is dedicated to unparalleled customer service. The company works closely with its clients, offering tailored solutions and project consultations to ensure that their specific requirements are met. By taking a collaborative approach, [PCB Assembly Firm] establishes long-term relationships with its clients, fostering a sense of trust and reliability.Looking ahead, [PCB Assembly Firm] aims to continue its growth trajectory by staying at the forefront of technological advancements in the PCB assembly industry. The company plans to invest further in research and development to better serve its clients' evolving needs and to expand its geographic reach.About [PCB Assembly Firm]:[PCB Assembly Firm] is a leading PCB assembly firm based in [City, State]. The company provides comprehensive PCB assembly services, utilizing cutting-edge technology, world-class equipment, and a skilled workforce to meet the diverse needs of its clientele. With a commitment to quality, efficiency, and customer satisfaction, [PCB Assembly Firm] has built a reputation as a trusted and reliable PCB assembly partner.Media Contact:[Person Name][Title][Company Name][Email Address][Phone Number]

Domestic PCB Assembly SMT Grows Strong in China as Electronics Manufacturing Flourishes

China SMT PCB Assembly: Boosting Electronics Manufacturing in ChinaChina has emerged as a global manufacturing powerhouse, playing a pivotal role in various industries. One such industry is electronics manufacturing, and one of the key players in this sector is China PCB Assembly SMT. With a strong commitment to quality and advanced technology, this company has succeeded in establishing itself as a reliable partner for electronics manufacturing needs.China PCB Assembly SMT is a leading provider of printed circuit board assembly (PCBA) services in China. The company offers a wide range of services, including surface mount technology (SMT), through-hole technology (THT), and mixed technology assembly. Their state-of-the-art facilities are equipped with advanced machinery, ensuring precise and efficient assembly processes.With a focus on high-quality production, China PCB Assembly SMT adheres to strict quality control measures throughout every stage of the manufacturing process. The company has obtained ISO 9001 certification, demonstrating its commitment to meeting international quality standards. These stringent quality control measures ensure that each product delivered by China PCB Assembly SMT meets or exceeds customer expectations.Apart from quality, China PCB Assembly SMT also places great emphasis on technological innovation. By investing in the latest manufacturing equipment and employing a highly skilled workforce, they are able to stay at the forefront of technological advancements in the industry. This continuous integration of new technologies enables China PCB Assembly SMT to offer efficient, cost-effective, and cutting-edge assembly solutions to their clients.One of the biggest advantages of partnering with China PCB Assembly SMT is their focus on providing comprehensive services. The company offers complete turnkey solutions, starting from PCB design and layout, to component sourcing, assembly, and testing. This end-to-end approach streamlines the manufacturing process and saves clients time and resources.China PCB Assembly SMT serves a wide array of industries, including consumer electronics, telecommunications, automotive, medical devices, and industrial equipment. With their extensive experience and expertise, they are able to cater to the unique requirements of each industry, ensuring that the final products are of the highest quality.In order to meet the growing demands of the global market, China PCB Assembly SMT has also expanded its production capabilities. They have established larger manufacturing facilities and implemented automated production lines to increase productivity. This expansion allows them to handle large-scale orders while maintaining the same level of quality and efficiency.Furthermore, China PCB Assembly SMT is committed to environmental sustainability. They have implemented eco-friendly manufacturing practices and utilize recyclable materials whenever possible. By prioritizing sustainability, the company not only reduces its environmental impact but also aligns with the changing demands of global markets that seek environmentally conscious electronics manufacturers.China PCB Assembly SMT's dedication to quality, technology, and comprehensive services has earned them recognition and trust from both domestic and international clients. Their commitment to meeting customer requirements, along with their competitive pricing, has made them one of the leading PCB assembly service providers in China.In conclusion, China PCB Assembly SMT plays a significant role in boosting electronics manufacturing in China. With their state-of-the-art facilities, advanced technology, and commitment to quality, the company has become a trusted partner for PCB assembly needs. By offering comprehensive services and continuously investing in innovation, China PCB Assembly SMT is well-positioned to meet the evolving demands of the global electronics market.

Industry Booms as Mass Production Takes Center Stage

[News Title][Company Name] Embarks on Mass Production to Meet Growing Demands[City, Date] - [Company Name], a leading global manufacturer in [industry], has recently announced its expansion plans for mass production, aimed towards meeting the increasing demands of customers worldwide. This strategic move comes in response to the thriving market and the need to streamline operations and optimize production capabilities.With its inception in [year], [Company Name] has steadily established itself as a pioneer in the [industry] sector. The company's commitment to quality, innovation, and customer satisfaction has earned it a reputable position in the market. Through continuous investment in research and development, [Company Name] has achieved remarkable breakthroughs, allowing it to introduce cutting-edge technology, products, and solutions.Acknowledging the need to keep up with the ever-evolving demands of industries such as [industry] and cater to the global markets, [Company Name] has decided to ramp up its mass production capabilities. The expansion plans involve strategic partnerships, investments in advanced machinery and technology, and the establishment of additional production facilities in key locations.Speaking with optimism about this expansion, [Company Name]'s CEO, [CEO's Name], mentioned, "We are thrilled to announce our ambitious mass production plans. As one of the market leaders in [industry], it is our responsibility to meet the increasing demands of our customers while maintaining the highest standards of quality and efficiency. This strategic move will enable us to stay competitive, satisfy market needs, and strengthen our global presence."The decision to embark on mass production is backed by extensive market research and detailed analysis of industry trends. With numerous successful pilot projects and early adopter programs, [Company Name] has received positive response and reassurance from key customers and stakeholders. The company's commitment to environmental sustainability is also reflected in the implementation of energy-efficient processes and the usage of eco-friendly materials throughout the production cycle.[Company Name]'s mass production plans are set to bring numerous benefits to both the company and its customers. The increased production capacity will lead to shorter lead times and faster delivery of products. Moreover, it will allow for better cost management and improved economies of scale, thereby offering customers competitive pricing options.In addition to meeting the growing demands of existing markets, the expansion will also enable [Company Name] to explore new business opportunities. With enhanced production capabilities, the company aims to expand its reach into untapped markets and cater to emerging customer needs. The increased output will create new employment opportunities, providing a boost to local economies and fostering economic growth.Looking towards the future, [Company Name]'s mass production strategy lays a solid foundation for sustained growth and continued success. The company is committed to maintaining its reputation as a reliable and innovative industry leader by staying at the forefront of technological advancements and constantly improving its manufacturing processes.About [Company Name]:[Company Name] is a global leader in the [industry] sector, specializing in the manufacturing of [products]. With a rich history dating back to [year], the company has continuously strived for excellence through innovation and quality. [Company Name] holds a strong commitment to its customers, sustainability, and social responsibility, making it a preferred choice for businesses worldwide. For more information, please visit [Company Website].Press Contact:[Media Relations Contact Name][Title][Email][Phone Number]

Latest Developments in the Electronics Manufacturing Industry Revealed

[News Title]SMT Electronics Manufacturing Company Streamlines Production Processes for Enhanced Manufacturing Efficiency[News Body][City name], [Date] - SMT Electronics Manufacturing, a leading company in the electronics manufacturing industry, is revolutionizing the way electronics are produced. By combining state-of-the-art technology with a relentless focus on innovation and efficiency, the company is setting new industry standards.SMT Electronics Manufacturing has been at the forefront of electronics manufacturing for over two decades, consistently delivering high-quality products to global customers. With a diverse portfolio of clients ranging from small startups to multinational corporations, the company has established itself as a trusted partner in the industry.By leveraging its extensive experience and expertise, SMT Electronics Manufacturing has become synonymous with cutting-edge technology and efficient manufacturing processes. The company's commitment to innovation has propelled it to the forefront of the electronics manufacturing sector, with a reputation for delivering products that meet and exceed customer expectations.One of the key factors behind SMT Electronics Manufacturing's success is its relentless pursuit of manufacturing efficiency. Realizing the need to optimize production processes, the company has invested heavily in advanced technology and automation systems. By embracing the latest developments in robotics, artificial intelligence, and data analytics, SMT Electronics Manufacturing has streamlined its operations, resulting in increased productivity and reduced costs.SMT Electronics Manufacturing's state-of-the-art factory is a testament to its commitment to excellence. Equipped with cutting-edge machinery and production lines, the facility operates at peak efficiency, allowing the company to meet customer demands with ease. From the initial design phase to the final product assembly, every step of the manufacturing process is closely monitored and optimized to ensure precision and quality.The company's dedication to quality is further exemplified by its stringent quality control measures. SMT Electronics Manufacturing adheres to industry-leading standards and certifications, ensuring that every product leaving its facility is of the highest quality. By conducting regular audits and inspections, the company maintains its commitment to delivering excellence in every aspect of its operations.Sustainability and environmental responsibility are also key pillars of SMT Electronics Manufacturing's business philosophy. Recognizing the importance of minimizing its ecological footprint, the company has implemented various initiatives to promote eco-friendly practices. From utilizing energy-efficient machinery to recycling waste materials, SMT Electronics Manufacturing is actively working towards a greener future.In addition to its commitment to manufacturing excellence, SMT Electronics Manufacturing also places a strong emphasis on customer satisfaction. The company's dedicated customer service team works closely with clients to understand their specific requirements and provide tailored solutions. By fostering long-term partnerships and responsive communication, SMT Electronics Manufacturing has cultivated a loyal customer base that values its commitment to quality and reliability.Looking towards the future, SMT Electronics Manufacturing aims to continue setting new benchmarks in the electronics manufacturing industry. By investing in research and development and staying ahead of the latest technological advancements, the company endeavors to remain at the forefront of innovation. Moreover, SMT Electronics Manufacturing plans to expand its global reach and forge new partnerships that will further solidify its position as a leader in the industry.About SMT Electronics Manufacturing:SMT Electronics Manufacturing is a renowned electronics manufacturing company based in [City, Country]. With a strong emphasis on innovation, efficiency, and customer satisfaction, the company has established itself as a trusted partner for clients worldwide. With a wide range of services including design, production, and quality control, SMT Electronics Manufacturing delivers cutting-edge products that meet and exceed industry standards.For more information, please visit [Company website].[PR Contact][Contact Name][Position][Email][Phone Number]

Dip Plug-In Process Factory: Streamlining the Manufacturing Process for Optimal Results

Dip Plug-In Process Factory: Revolutionizing Manufacturing InnovationIn today's fast-paced world, the constant demand for innovation and efficiency has never been higher. Industries are constantly seeking new ways to streamline their manufacturing processes and develop cutting-edge technologies. In line with this trend, a groundbreaking Plug-In Process Factory has emerged, poised to transform the industry, thanks to its revolutionary manufacturing capabilities.The newly established Dip Plug-In Process Factory aims to redefine conventional manufacturing processes by implementing state-of-the-art technologies. This cutting-edge factory is backed by an experienced team of highly skilled engineers and technicians who strive to develop innovative manufacturing solutions for various industries.Dip Plug-In Process Factory prides itself on its ability to provide end-to-end manufacturing solutions tailored to each client's specific needs. From the initial design phase to production and final assembly, this factory offers a seamless process that ensures optimal manufacturing efficiency and top-notch quality.One of the key advantages that sets Dip Plug-In Process Factory apart from its competitors is its utilization of plug-in manufacturing processes. This innovative approach allows for greater flexibility and adaptability during the production stage. With plug-in technology, manufacturers can easily modify and customize their processes to accommodate changes in product design, market demand, or unexpected challenges.By implementing plug-in manufacturing processes, Dip Plug-In Process Factory helps businesses save valuable time and resources. The ability to make quick adjustments along the production line ensures that companies can respond swiftly to market trends and customer demands, gaining a competitive edge.Moreover, Dip Plug-In Process Factory understands the importance of sustainability in today's manufacturing landscape. The factory places a strong emphasis on eco-friendly practices, integrating environmentally conscious policies into their manufacturing processes. From energy-efficient machinery to waste reduction strategies, this factory strives to minimize its environmental impact while maximizing production capabilities.Dip Plug-In Process Factory's commitment to sustainability extends beyond their manufacturing practices. They actively engage in research and development to explore cleaner and more sustainable materials for use in production. By continuously seeking innovative solutions, Dip Plug-In Process Factory aims to contribute to a greener, more sustainable future for the manufacturing industry.Furthermore, the factory also offers comprehensive training and consulting services, providing clients with the tools and knowledge necessary to optimize their manufacturing processes. By partnering with Dip Plug-In Process Factory, businesses gain access to a wealth of expertise and insights into enhancing their production capabilities.With a proven track record of successful projects across diverse industries, Dip Plug-In Process Factory has established itself as a trusted partner for businesses aspiring to revolutionize their manufacturing processes. Through their unwavering commitment to innovation, sustainability, and efficiency, this factory has become a driving force behind the transformation of the manufacturing landscape.In conclusion, Dip Plug-In Process Factory is revolutionizing the manufacturing industry through its state-of-the-art plug-in manufacturing processes. With a focus on innovation, sustainability, and customization, this factory offers end-to-end manufacturing solutions tailored to each client's needs. By embracing plug-in technology, Dip Plug-In Process Factory enables businesses to adapt quickly to market changes and streamline their production processes. With a dedicated team of experts, a commitment to sustainability, and comprehensive training and consulting services, this factory is leading the way towards a more efficient and eco-friendly future for manufacturing.

China PCB Assembly Steps: A Comprehensive Guide to PCB Assembly in China

Title: China PCB Assembly Steps: A Guide to Efficient and Reliable Electronic Manufacturing ProcessesIntroduction:With the rapid advancements in technology, the demand for high-quality and reliable electronic devices has witnessed a significant surge. Chinese companies have emerged as global leaders in the field of PCB (Printed Circuit Board) assembly, offering efficient and cost-effective solutions for the manufacturing of electronic products. In this article, we will delve into the step-by-step process of PCB assembly in China, highlighting the key aspects and advantages that make it a preferred choice among manufacturers worldwide.Section 1: Introduction to PCB Assembly in ChinaChina has become known for its exceptional capabilities in PCB assembly, thanks to its vast industrial infrastructure, skilled labor force, and state-of-the-art equipment. Moreover, the competitive production costs and flexible manufacturing capabilities have made PCB assembly services in China highly sought-after by various industries, including telecommunications, consumer electronics, automotive, aerospace, and medical devices.Section 2: PCB Assembly Steps - Efficiency and Precision2.1 Design and Prototyping:The first step in the PCB assembly process involves design and prototyping. Skilled engineers and designers collaborate with clients to develop a comprehensive layout, ensuring all specifications and requirements are met. With the aid of advanced software tools, the design is then translated into a physical prototype.2.2 Component Sourcing:China's vast network of component suppliers enables efficient sourcing of high-quality electronic components required for PCB assembly. This step involves meticulous verification and selection of components based on their quality, compatibility, and reliability.2.3 PCB Manufacturing:Once the design and components are finalized, PCB manufacturing commences. Specialized equipment ensures the precise etching and fabrication of the PCB, adhering to high-quality standards specified by international regulations.2.4 SMT Assembly:Surface Mount Technology (SMT) assembly is a crucial step in Chinese PCB assembly, where components are mounted directly onto the PCB surface. Automated pick-and-place machines ensure accurate placement, significantly enhancing the efficiency and reliability of the assembly process.2.5 Inspection and Testing:After SMT assembly, rigorous inspection and testing procedures are undertaken to ensure the PCB's quality and functionality. Advanced testing equipment is employed to identify any defects or malfunctions, enabling timely rectification before proceeding to the next stage.2.6 Through-Hole Assembly:In cases where through-hole components are required, a selective soldering process is employed, ensuring secure and reliable connections between the through-hole components and the PCB.2.7 Quality Control and Assurance:China prioritizes stringent quality control measures at every stage of the PCB assembly process. Trained quality control personnel conduct inspections to guarantee the adherence to industry standards and customer specifications.Section 3: Advantages of China PCB Assembly3.1 Cost-effectiveness:Compared to other regions, China offers competitive manufacturing costs without compromising on quality, making it a cost-effective solution for businesses worldwide.3.2 Quick Turnaround Time:Chinese PCB assembly companies are known for their ability to deliver products within short lead times, ensuring timely market entry for customers' electronic devices.3.3 Advanced Infrastructure and Technology:China boasts a sophisticated industrial infrastructure, equipped with cutting-edge facilities, enabling efficient and precise PCB assembly processes. The application of advanced technologies ensures high-quality outputs and reliable electronic products.3.4 Customization and Flexibility:Chinese PCB assembly companies excel in providing tailored solutions to meet specific project requirements. Their flexibility in accommodating various orders, whether small-scale or large-scale, makes them an ideal choice for businesses with diverse needs.Conclusion:With their efficient and reliable PCB assembly processes, China has cemented its position as a global leader in the electronics manufacturing industry. The step-by-step guide presented in this article offers insights into the meticulous and advanced methodologies employed by Chinese companies. The cost-effectiveness, quick turnaround time, advanced infrastructure, and flexible manufacturing capabilities provided by these companies make China a preferred destination for businesses seeking high-quality PCB assembly services.

Discover the Leading Source for High-Quality PCB Assembly Services

Title: One-Stop PCB Assembly Supplier Streamlines Manufacturing Process to Meet Industry DemandsIntroduction:In an era marked by unprecedented technological advancements, the demand for printed circuit boards (PCBs) has skyrocketed across various industries. To address this growing need, an industry-leading PCB assembly supplier has emerged as a pioneer in the field, offering comprehensive services to meet the electronic manufacturing requirements of companies worldwide. This news article will delve deep into the workings of this one-stop solution provider and explore how they have revolutionized the industry with their efficient manufacturing processes.Company Overview:With a vision to provide cutting-edge PCB assembly services, the company has quickly risen to prominence as a top-tier supplier in the industry. Renowned for its unwavering commitment to quality, innovation, and customer satisfaction, the company has amassed a loyal client base that spans multiple sectors, including automotive, aerospace, telecommunications, and consumer electronics.Streamlined Manufacturing Process:The success of this one-stop PCB assembly supplier can be primarily attributed to its streamlined manufacturing process, which ensures maximum efficiency without compromising on quality. By blending the latest technological advancements with a skilled workforce, the company has perfected the art of PCB manufacturing, meeting the stringent demands of the modern market.Advanced Facilities and Equipment:At the core of the company's operational excellence lies state-of-the-art facilities and cutting-edge equipment that aid in the flawless production of PCBs. The supplier has made substantial investments in upgrading their infrastructure, allowing them to handle projects of various complexities with ease. Equipped with advanced automated machinery, precision instruments, and high-quality materials, the company guarantees robust PCB assembly that meets international standards.Experienced Engineering Team:Behind the scenes, a team of highly experienced engineers play a crucial role in the success of the PCB assembly process. These experts possess a wealth of technical knowledge and expertise and work collaboratively with clients to design and develop PCBs that meet their specific requirements. With their meticulous attention to detail and focus on continuous improvement, the engineering team ensures that every PCB leaving the facility is of exceptional quality and reliability.Quality Assurance Measures:As reliability is a critical factor in the electronic manufacturing industry, the company has implemented rigorous quality assurance measures at every stage of the production process. From stringent material inspections to thorough testing and validation procedures, the supplier leaves no stone unturned to deliver faultless PCB assemblies. Furthermore, the company adheres to industry standards, certifications, and compliance regulations, imparting an added layer of trust among their clientele.Customization and Flexibility:Recognizing the diverse needs of their customers, the one-stop supplier offers a high degree of customization and flexibility in their services. With the capacity to handle both small-scale production runs and large-scale manufacturing projects, the company caters to organizations of all sizes. Through open communication channels, the company ensures that each client's unique specifications are met, fostering long-term partnerships based on trust and reliability.Global Reach and Timely Delivery:Operating on a global scale, the supplier has established a robust supply chain network that enables them to serve clients across continents. With strategically located and fully equipped manufacturing facilities, the company guarantees expedited delivery times without compromising quality. This global reach positions the one-stop PCB assembly supplier as a preferred choice for multinational companies seeking efficient and reliable manufacturing solutions.Conclusion:In an increasingly competitive market, this one-stop PCB assembly supplier has emerged as a game-changer, revolutionizing the manufacturing process and meeting the dynamic demands of various industries. With their technologically advanced facilities, skilled workforce, commitment to quality, and global reach, the company continues to build a strong reputation as a leader in the field. As the demand for PCB assemblies continues to grow, this supplier is well-positioned to play a pivotal role in shaping the electronic manufacturing landscape for years to come.