Accelerating PCB Prototype Turnaround: Unveiling China's Efficient Solution

By:Admin

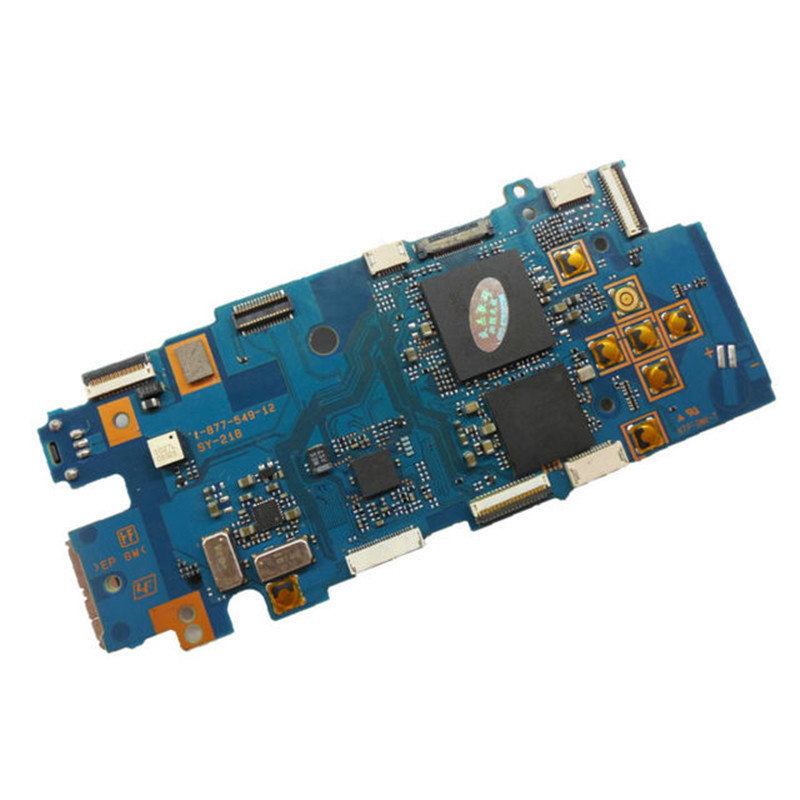

With the fast-paced advancements in technology, the demand for efficient and quick printed circuit board prototypes has increased exponentially. To address this growing need, China Fast Turn PCB Prototype Provider has invested heavily in state-of-the-art machinery and equipment. This has allowed them to streamline their production process, drastically reducing lead times without compromising on quality.

One of the key factors that sets China Fast Turn PCB Prototype Provider apart from its competitors is its comprehensive understanding of customer requirements. The company recognizes that each project has unique specifications and works closely with clients to ensure that their exact needs are met. From initial design to final production, China Fast Turn PCB Prototype Provider offers exceptional customer support throughout the entire process.

Another aspect that enables China Fast Turn PCB Prototype Provider to stand out in the industry is its team of highly skilled and experienced engineers and technicians. With extensive knowledge in the field, these experts are equipped to handle complex designs and ensure flawless execution. Their expertise combined with the latest technology allows for rapid prototyping, reducing the time needed for testing and modifications.

China Fast Turn PCB Prototype Provider realizes the importance of meeting strict deadlines, especially in industries where time-to-market is crucial. By implementing efficient production techniques and maintaining a responsive supply chain, the company ensures that clients receive their PCB prototypes in the shortest possible time. This not only allows businesses to stay ahead of the competition but also saves valuable resources.

The company takes pride in its commitment to quality control throughout the entire manufacturing process. Each PCB prototype undergoes rigorous testing to verify its functionality and durability. China Fast Turn PCB Prototype Provider adheres to international standards and certifications, ensuring that their products meet the highest quality requirements.

In addition to their exceptional production capabilities, China Fast Turn PCB Prototype Provider offers competitive pricing that suits varying budgetary constraints. By leveraging their efficient production process and economies of scale, they are able to provide high-quality prototypes at affordable prices, making them an ideal choice for both small businesses and large corporations.

China Fast Turn PCB Prototype Provider's dedication to sustainability is also noteworthy. They prioritize environmental responsibility by implementing eco-friendly practices in their production facilities. The company actively seeks ways to reduce waste, conserve energy, and minimize their carbon footprint, making them a socially conscious partner for clients who value sustainability.

As China Fast Turn PCB Prototype Provider continues to enhance its expertise and capabilities, the company remains committed to pushing the boundaries of innovation within the printed circuit board industry. With its advanced technology, fast turnaround times, exceptional customer service, and commitment to quality and sustainability, China Fast Turn PCB Prototype Provider has established itself as a reliable and trusted partner for businesses in need of rapid and high-quality PCB prototypes.

Company News & Blog

Master the Art of Surface Mounting Soldering Techniques for Exceptional Results

Surface Mounting Soldering Revolutionizes Electronic ManufacturingIn today's rapidly evolving world, technology plays an integral role in our daily lives. From smartphones to smart homes, the demand for advanced electronic devices continues to soar. Behind the scenes, electronic manufacturers strive to keep up with consumer expectations by constantly upgrading their manufacturing processes. One such breakthrough is surface mounting soldering, a technique that has revolutionized the industry by offering speed, precision, and efficiency.Surface mounting soldering, or SMT, is a method used to assemble electronic circuits where the components are directly mounted onto the surface of a printed circuit board (PCB). Unlike traditional through-hole soldering, which involves inserting leads through holes on the PCB, SMT eliminates the need for holes and allows for smaller, more compact devices. This technique has become increasingly popular due to its ability to meet the growing demand for smaller, smarter, and more portable electronic products.With the rise of SMT, manufacturers can now design and produce devices that are not only aesthetically appealing but also highly-functional. By eliminating the bulky components and minimizing the space required, SMT allows for the creation of sleek and lightweight products that fit seamlessly into our increasingly connected world. From wearables to Internet of Things (IoT) devices, the applications of SMT are virtually limitless.One of the key benefits of surface mounting soldering is its ability to improve the speed and efficiency of the manufacturing process. Traditional through-hole soldering involves manually soldering each component onto the PCB, a time-consuming and labor-intensive task. In contrast, SMT utilizes automated pick-and-place machines that can accurately place multiple components simultaneously, reducing the assembly time significantly. This results in faster production cycles, allowing manufacturers to meet consumer demands more efficiently and cost-effectively.Furthermore, SMT offers superior precision and reliability compared to through-hole soldering. The automated machines used in SMT ensure consistent component placement, guaranteeing a higher level of accuracy. The solder joints formed in SMT also tend to be smaller and more reliable, as the surface tension distributes the molten solder evenly and creates stronger connections. This ensures the long-term reliability of the electronic devices and reduces the risk of failures or malfunctions.In addition to its speed and precision, surface mounting soldering also promotes sustainability in electronic manufacturing. SMT allows manufacturers to minimize the amount of waste generated during the assembly process. With through-hole soldering, excess leads and wires are often cut off and discarded, leading to unnecessary material wastage. However, SMT's minimalistic design approach reduces the amount of material required and maximizes the utilization of resources, making it a greener option for the industry.{Company intro}: As a leading innovator in the electronics manufacturing industry, our company is at the forefront of adopting SMT technology. We understand the increasing demands of consumers for smaller, faster, and smarter devices, and aim to meet those demands through the integration of surface mounting soldering into our manufacturing processes. Our state-of-the-art facilities house the latest pick-and-place machines and cutting-edge SMT equipment, enabling us to deliver high-quality products with exceptional precision and reliability.With the advent of surface mounting soldering, the landscape of electronic manufacturing has been forever transformed. This advanced technique has not only improved the quality, performance, and aesthetics of electronic devices but has also enhanced the overall manufacturing process. By embracing the benefits of SMT, manufacturers can meet consumer demands more efficiently, reduce waste, and contribute to a more sustainable future in the industry. As technology continues to evolve, surface mounting soldering will undoubtedly remain a vital tool for innovators pushing the boundaries of what is possible in the electronic realm.

Revolutionizing Manufacturing: The Benefits of High Volume Production

[Headline]: Major Company Achieves High Volume Production, Demonstrating Commitment to Industry Growth[Sub-heading]: Introduction of the Company and its Contributions to the Industry[Date]: [Insert Date][CITY], [STATE] - [Company Name], a leading player in the [industry/sector], has recently achieved remarkable success with its high-volume production process. The company's commitment to continuous improvement, technological advancements, and the pursuit of excellence has solidified its position as a trailblazer in the industry. With a focus on innovation and unmatched production capabilities, [Company Name] has become a benchmark for efficiency and reliability.[Company Name] has a rich history of serving the [industry/sector] for over [number] years. Founded in [year], the company has grown exponentially through its dedication to superior quality, customer satisfaction, and sustainable practices. From modest beginnings, [Company Name] has transformed into a global powerhouse, boasting an extensive network of production facilities and customers worldwide.Central to [Company Name]'s success is its commitment to high-volume production. This process enables the company to meet ever-increasing demand while maintaining consistent quality and competitive pricing. By leveraging advanced technologies, automation, and streamlined workflows, [Company Name] has revolutionized the industry's approach to large-scale manufacturing.To support its high-volume production capabilities, [Company Name] has made substantial investments in cutting-edge machinery, state-of-the-art equipment, and research and development initiatives. The company's commitment to innovation places it at the forefront of the industry, consistently introducing groundbreaking solutions that enhance productivity, reduce waste, and improve overall efficiency.The benefits of high-volume production are not limited to [Company Name] alone; the industry as a whole stands to gain from this achievement. By setting new benchmarks for efficiency and productivity, [Company Name] paves the way for increased competitiveness, supply chain optimization, and overall sector growth. Moreover, the company's commitment to sustainable practices ensures that high-volume production is achieved without compromising environmental responsibility.[Company Name]'s dedication to sustainable production is evident in its adoption of renewable energy sources, waste reduction strategies, and responsible sourcing. By aligning profitability with environmental stewardship, the company sets an example for others in the industry and serves as a catalyst for positive change. High-volume production, when executed responsibly, can drive economic growth while minimizing the ecological footprint associated with manufacturing processes.The success of [Company Name]'s high-volume production process has garnered praise from industry experts and customers alike. The ability to consistently deliver large quantities of products while maintaining quality and adhering to tight timelines is a testament to the company's prowess. In an ever-evolving market, where customer demands are on the rise, [Company Name] stands as a reliable partner that can meet and exceed expectations.Looking ahead, [Company Name] intends to further enhance its high-volume production capabilities by embracing emerging technologies such as artificial intelligence, data analytics, and predictive modeling. These investments will facilitate even greater efficiency, reliability, and scalability, cementing the company's position as an industry leader.In conclusion, [Company Name]'s recent achievement in high-volume production underscores its unwavering commitment to industry growth, innovation, and sustainability. By combining advanced technologies, state-of-the-art production facilities, and a dedicated workforce, the company sets new industry standards and showcases the immense potential of large-scale manufacturing. As [Company Name] continues to push boundaries, the industry will undoubtedly benefit, fostering progress and prosperity for all involved.

Dip Plug-In Process Factory: Streamlining the Manufacturing Process for Optimal Results

Dip Plug-In Process Factory: Revolutionizing Manufacturing InnovationIn today's fast-paced world, the constant demand for innovation and efficiency has never been higher. Industries are constantly seeking new ways to streamline their manufacturing processes and develop cutting-edge technologies. In line with this trend, a groundbreaking Plug-In Process Factory has emerged, poised to transform the industry, thanks to its revolutionary manufacturing capabilities.The newly established Dip Plug-In Process Factory aims to redefine conventional manufacturing processes by implementing state-of-the-art technologies. This cutting-edge factory is backed by an experienced team of highly skilled engineers and technicians who strive to develop innovative manufacturing solutions for various industries.Dip Plug-In Process Factory prides itself on its ability to provide end-to-end manufacturing solutions tailored to each client's specific needs. From the initial design phase to production and final assembly, this factory offers a seamless process that ensures optimal manufacturing efficiency and top-notch quality.One of the key advantages that sets Dip Plug-In Process Factory apart from its competitors is its utilization of plug-in manufacturing processes. This innovative approach allows for greater flexibility and adaptability during the production stage. With plug-in technology, manufacturers can easily modify and customize their processes to accommodate changes in product design, market demand, or unexpected challenges.By implementing plug-in manufacturing processes, Dip Plug-In Process Factory helps businesses save valuable time and resources. The ability to make quick adjustments along the production line ensures that companies can respond swiftly to market trends and customer demands, gaining a competitive edge.Moreover, Dip Plug-In Process Factory understands the importance of sustainability in today's manufacturing landscape. The factory places a strong emphasis on eco-friendly practices, integrating environmentally conscious policies into their manufacturing processes. From energy-efficient machinery to waste reduction strategies, this factory strives to minimize its environmental impact while maximizing production capabilities.Dip Plug-In Process Factory's commitment to sustainability extends beyond their manufacturing practices. They actively engage in research and development to explore cleaner and more sustainable materials for use in production. By continuously seeking innovative solutions, Dip Plug-In Process Factory aims to contribute to a greener, more sustainable future for the manufacturing industry.Furthermore, the factory also offers comprehensive training and consulting services, providing clients with the tools and knowledge necessary to optimize their manufacturing processes. By partnering with Dip Plug-In Process Factory, businesses gain access to a wealth of expertise and insights into enhancing their production capabilities.With a proven track record of successful projects across diverse industries, Dip Plug-In Process Factory has established itself as a trusted partner for businesses aspiring to revolutionize their manufacturing processes. Through their unwavering commitment to innovation, sustainability, and efficiency, this factory has become a driving force behind the transformation of the manufacturing landscape.In conclusion, Dip Plug-In Process Factory is revolutionizing the manufacturing industry through its state-of-the-art plug-in manufacturing processes. With a focus on innovation, sustainability, and customization, this factory offers end-to-end manufacturing solutions tailored to each client's needs. By embracing plug-in technology, Dip Plug-In Process Factory enables businesses to adapt quickly to market changes and streamline their production processes. With a dedicated team of experts, a commitment to sustainability, and comprehensive training and consulting services, this factory is leading the way towards a more efficient and eco-friendly future for manufacturing.

Leading Manufacturer of High-Quality PCBA Circuit Boards for Various Industries

Title: Leading PCBA Circuit Board Factory Revolutionizes Electronics ManufacturingIntroduction:(Date, Place) - As the demand for advanced electronic devices continues to soar, the technology industry relies heavily on the production of high-quality printed circuit board assemblies (PCBAs) to enable the seamless functioning of these devices. Breaking new ground in the field, the renowned PCBA Circuit Board Factory leverages state-of-the-art technology and a commitment to innovation to deliver unparalleled PCBAs. Operating under the guidance of their visionary CEO (), this factory guarantees optimal performance, reliability, and affordability in every product they manufacture.Paragraph 1:Founded on the principle of innovation, the PCBA Circuit Board Factory has quickly emerged as a leading player in the electronics manufacturing market. Their cutting-edge facilities, located in (), boast an exceptional combination of advanced machinery, extensive research and development labs, and a highly skilled workforce. These resources, combined with stringent quality control measures, enable the company to consistently deliver top-of-the-line PCBAs that meet the ever-evolving needs of the industry.Paragraph 2:With a commitment to technological advancement, the factory employs an eco-friendly manufacturing process that adheres to international standards for responsible production. The factory's management places great emphasis on sustainability, ensuring that energy consumption is optimized across all stages of production. By minimizing waste and implementing recycling measures, the company maintains its dedication to reducing its ecological footprint.Paragraph 3:In addition to adhering to environmental standards, the PCBA Circuit Board Factory prioritizes its employees' well-being. By offering comprehensive training programs and competitive salaries, the factory attracts and retains a highly skilled workforce. The employees are trained in the latest technologies and industry practices, guaranteeing that each PCBA manufactured is of the highest quality. Furthermore, the factory fosters a dynamic and inclusive work environment that encourages collaboration and innovation.Paragraph 4:The PCBA Circuit Board Factory's dedication to research and development remains one of its key differentiating factors. Investing heavily in R&D, the factory constantly seeks ways to improve its manufacturing processes and enhance product performance. This commitment ensures that the factory stays at the forefront of technological advancements, enabling it to meet customer demands for increasingly complex, versatile, and efficient PCBAs.Paragraph 5:The factory's reputation for exceptional quality has resulted in successful partnerships with renowned electronic device manufacturers across the globe. By consistently delivering reliable and high-performing PCBAs, the factory has built a solid client base that spans industries such as telecommunications, automotive, medical devices, and consumer electronics.Paragraph 6:Looking toward the future, the PCBA Circuit Board Factory aims to expand its global reach and further diversify its product portfolio. By exploring emerging technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and 5G connectivity, the factory positions itself as an industry leader capable of meeting tomorrow's demands. Their commitment to R&D ensures that they are prepared to take on the challenges of new technologies and embrace the opportunities they present.Conclusion:With its state-of-the-art facilities, commitment to quality, and a dedication to innovation, the PCBA Circuit Board Factory has revolutionized the electronics manufacturing industry. By consistently delivering high-quality PCBAs while adhering to environmental and ethical standards, the factory has earned a reputation synonymous with excellence. As the demand for advanced electronic devices continues to grow, this factory is well-positioned to meet and exceed the industry's evolving expectations, cementing their status as a global leader in the field.

Optimized PCB Assembly Flexible Factory for Efficient Manufacturing

[Company Introduction]Pcb Assembly Flexible Factory is a leading electronics manufacturing company that specializes in the production of printed circuit boards (PCBs) and assembly services. With a strong commitment to quality, innovation, and customer satisfaction, this flexible factory offers state-of-the-art facilities, advanced technologies, and a highly skilled workforce to meet the diverse needs of its clients.Equipped with modern machinery and equipment, Pcb Assembly Flexible Factory ensures efficient production processes while maintaining the highest standards of quality control. The company's team of engineers and technicians are experienced in working with various materials, ensuring a flexible approach to meet the specific requirements of different industries, including automotive, telecommunications, aerospace, consumer electronics, and more.With strict adherence to industry regulations and certifications such as ISO 9001, ISO 14001, and IPC-A-610, Pcb Assembly Flexible Factory guarantees the reliability, functionality, and safety of its products. By offering comprehensive services, including component sourcing, PCB design, manufacturing, assembly, and testing, the company provides turnkey solutions to facilitate the entire product development cycle. This integrated approach not only reduces time-to-market but also optimizes cost-efficiency for clients.In addition to its commitment to quality, Pcb Assembly Flexible Factory also focuses on environmental sustainability. The company prioritizes green production methods, reducing waste and energy consumption to minimize its ecological footprint. By implementing eco-friendly practices, such as lead-free soldering processes and proper waste management, the factory ensures compliance with regulatory requirements and promotes a cleaner and greener approach to electronics manufacturing.[News Content]Pcb Assembly Flexible Factory: Revolutionizing Electronics Manufacturing with a Flexibility-oriented ApproachWith the constant advancements in technology and the increasing demands of various industries, the electronics manufacturing sector is facing the challenge of producing innovative and reliable products efficiently. Pcb Assembly Flexible Factory has recognized this need and developed a specialized approach to cater to the diverse requirements of its clients.By combining cutting-edge technologies, a skilled workforce, and a commitment to quality, Pcb Assembly Flexible Factory has positioned itself as a leader in the industry. The company's emphasis on flexibility allows them to adapt to ever-changing market trends, enabling them to provide custom solutions to their clients.One of the key factors that sets Pcb Assembly Flexible Factory apart from its competitors is its state-of-the-art facilities. Equipped with modern machinery and automated assembly lines, the factory ensures high-speed production without compromising on quality. By investing in advanced technologies, the company can offer a wide range of services, catering to the needs of small-scale businesses as well as multinational corporations.In addition to its advanced facilities, Pcb Assembly Flexible Factory boasts a highly skilled workforce. The company's engineers and technicians are trained in the latest industry standards and possess a deep understanding of various materials and processes. This enables them to provide expert guidance and assistance to clients in the design and manufacturing of their products. The factory's team is adept at handling complex projects, ensuring optimal functionality and reliability of the final product.By offering a turnkey solution, Pcb Assembly Flexible Factory streamlines the product development cycle for its clients. From sourcing components to designing and manufacturing PCBs, and finally assembling and testing the products, the company ensures a seamless and efficient process. This integrated approach not only saves time but also reduces costs for its clients, enabling them to focus on their core competencies.Furthermore, Pcb Assembly Flexible Factory prioritizes environmental sustainability in its operations. By adhering to eco-friendly practices and regulations, the factory minimizes its impact on the environment. Lead-free soldering processes, proper waste management, and energy-efficient machinery are just a few examples of the company's commitment to green manufacturing. This aligns with the growing global focus on sustainability, making Pcb Assembly Flexible Factory an attractive partner for environmentally conscious businesses.In conclusion, Pcb Assembly Flexible Factory's emphasis on flexibility, advanced technology, skilled workforce, and commitment to quality and sustainability sets the company apart in the electronics manufacturing sector. By offering a comprehensive range of services and catering to diverse client requirements, the factory has established itself as a reliable and innovative partner for businesses across industries.

Boosting Efficiency in Electronic Assembly: A Comprehensive Guide

Contract Electronic Assembly, a leading provider of electronics manufacturing services, recently announced its expansion plans to meet the growing demand for high-quality electronic products. With a diverse range of capabilities and a commitment to customer satisfaction, the company is set to revolutionize the industry.Contract Electronic Assembly, or CEA, specializes in providing turnkey manufacturing solutions to businesses across various sectors. Their state-of-the-art facilities are equipped with cutting-edge technology and staffed by highly skilled professionals, ensuring the highest standards of quality and precision.In recent years, the demand for electronic products has skyrocketed, driven by technological advancements and increased consumer reliance on electronic devices. As a result, businesses are seeking trusted partners who can manage their entire manufacturing process efficiently and cost-effectively. CEA has emerged as a market leader in this domain, providing clients with end-to-end services that encompass design support, prototyping, testing, and full-scale production.With a focus on customer satisfaction, CEA goes above and beyond to understand client requirements and deliver tailor-made solutions. The company's team of experts collaborates closely with clients from the initial design phase, ensuring seamless integration of ideas and efficient execution. This approach allows businesses to speed up their time-to-market and gain a competitive edge.Furthermore, CEA recognizes the importance of quality control in the electronics manufacturing process. Stringent inspection and testing procedures are in place to catch any potential defects before the final products leave the facility. This commitment to quality assurance has earned CEA a reputation for delivering exceptional products that meet or exceed industry standards.To support their expansion plans, CEA has invested heavily in infrastructure and human resources. The company has recently acquired a larger facility to accommodate increased production capacity and enhance overall operational efficiency. Additionally, CEA continues to invest in employee training and development programs, ensuring a highly skilled workforce capable of delivering unparalleled craftsmanship.CEA's commitment to sustainability is also noteworthy. The company recognizes the impact of electronic waste on the environment and actively seeks ways to minimize its carbon footprint. By adhering to strict environmental regulations and promoting eco-friendly practices, CEA aims to contribute to a greener and more sustainable future.In a competitive industry, CEA stands out through its dedication to customer service, superior product quality, and proactive approach towards innovation. The company's ability to deliver end-to-end manufacturing solutions while maintaining flexibility and adaptability sets it apart from its competitors. Clients can rely on CEA to deliver products on time, within budget, and to the highest possible standards.As technology continues to evolve rapidly, Contract Electronic Assembly remains at the forefront of innovation, continuously exploring new manufacturing techniques and incorporating the latest advancements into their processes. With a proven track record of success, a commitment to excellence, and a customer-centric approach, CEA is well-positioned to thrive in the ever-changing electronics manufacturing industry.In conclusion, Contract Electronic Assembly's recent expansion plans demonstrate the company's commitment to meeting the increasing demand for high-quality electronic products. With a focus on customer satisfaction, product quality, and sustainability, CEA is poised to lead the industry by delivering top-notch manufacturing solutions. As technology advances and consumer demands rise, businesses can rely on CEA to be their trusted partner in bringing innovative electronic products to market.

Discover the Latest Updates on PCB Assembly Factories for Flexible Electronics

Flex PCB Assembly Factory: A Leader in Cutting-Edge Electronics ManufacturingIn an era where technology advancements are taking place at an unprecedented pace, the demand for flexible printed circuit boards (PCBs) has skyrocketed. These PCBs are revolutionizing the electronics industry due to their ability to bend, twist, and conform to various shapes, providing unparalleled design freedom and space optimization. With the growing market, it is imperative to have a reliable and efficient Flex PCB Assembly Factory that can meet the demands of this evolving industry.Introducing {}, a trailblazer in the field of Flex PCB manufacturing and assembly. With their state-of-the-art facilities and expertise, they have cemented their position as a leader in the industry. Their commitment to high-quality products and superior customer service has made them the go-to choice for many renowned electronics brands.{}'s factory is equipped with cutting-edge machinery and automated assembly lines, ensuring precision and efficiency in every product. Their team of highly skilled engineers and technicians has an in-depth understanding of the nuances of Flex PCBs, enabling them to provide customized solutions tailored to meet the unique requirements of each client.The company's customer-centric approach is evident in their focus on building long-lasting relationships with their clients. They not only provide exemplary manufacturing services but also offer comprehensive support throughout the entire product development cycle. From prototyping to volume production, {}, assists their clients at every stage, ensuring a smooth and hassle-free experience.One of the key differentiators that sets {} apart from the competition is their commitment to innovation. They continually invest in research and development to stay at the forefront of technological advancements. Their team of experts actively collaborates with clients, providing valuable insights and suggestions to optimize their PCB designs. This synergy between {} and their clients ensures that the final products boast superior quality and functionality.{} takes quality control seriously, employing stringent testing procedures at every stage of the manufacturing process. They adhere to international standards and certifications to guarantee that every product leaving their factory meets the highest industry standards. This unwavering commitment to quality has earned them a reputation for providing reliable and durable Flex PCBs.Environmental sustainability is another essential aspect of {}'s operations. They prioritize eco-friendly practices and have implemented measures to minimize their carbon footprint. From reducing energy consumption to adopting recyclable materials, {} plays its part in protecting our planet.With a global clientele spanning various industries, {} has established itself as a trusted partner in flex PCB assembly. They cater to diverse sectors such as consumer electronics, automotive, medical, telecommunications, and more. Their ability to cater to a wide range of applications showcases their adaptability and expertise in this dynamic industry.In conclusion, {}'s Flex PCB Assembly Factory is a force to be reckoned with in the electronics manufacturing world. From their cutting-edge facilities to their commitment to innovation, quality control, and sustainability, they have become the go-to choice for companies seeking top-notch flex PCB assembly. With {} as their partner, businesses can bring their visionary electronic designs to life, confident in the product's durability, reliability, and superior performance.

Circuit Card Assembly Factory: A Hub of Advanced Electronics Manufacturing

[Company Name] Opens State-of-the-Art Circuit Card Assembly Factory[City, State] - [Company Name], a leading provider of cutting-edge technology solutions, has recently unveiled its new state-of-the-art circuit card assembly factory in [City, State]. The facility marks a significant milestone in the company's expansion plans and is set to revolutionize the production and assembly of circuit cards.Spanning over [number] square feet, the newly built circuit card assembly factory is equipped with the latest cutting-edge technologies and advanced machinery. With a production capacity of [number] circuit cards per day, the facility is designed to meet the increasing demand for high-quality circuit card assembly solutions in various industries, including automotive, telecommunications, aerospace, and consumer electronics.[Company Name] has always been at the forefront of innovation and aims to deliver superior products that exceed customer expectations. The new factory is a testament to the company's commitment to excellence and its persistent efforts to provide best-in-class circuit card assembly services.The facility boasts a highly trained and skilled workforce, consisting of engineers, technicians, and quality control professionals who ensure the seamless assembly of circuit cards. Equipped with expertise in the latest manufacturing techniques and utilizing advanced equipment, the team guarantees the highest level of quality and reliability.The circuit card assembly process in the factory follows a meticulous and robust procedure to ensure maximum efficiency and accuracy. From component placement and solder paste printing to inspection and testing, each stage is executed with precision and attention to detail. The factory adheres to stringent quality standards and complies with all applicable industry regulations to deliver products that are unmatched in their quality and performance.By investing in state-of-the-art machinery and automated systems, [Company Name] can achieve enhanced precision, increased production speed, and reduced costs. The factory is equipped with cutting-edge robotics and computerized systems that optimize the assembly process, enabling quicker turnaround times without compromising on quality.One of the key features of the facility is its commitment to environmental sustainability. [Company Name] has incorporated green practices throughout the factory, focusing on minimizing waste, conserving energy, and adopting eco-friendly manufacturing processes. The company's dedication to sustainability aligns with its vision to create a greener future while providing innovative circuit card assembly solutions to its customers.The inauguration of the circuit card assembly factory reinforces [Company Name]'s position as a trusted partner for businesses looking for high-quality circuit cards. With the capacity to scale production based on customer requirements, the company is well-positioned to cater to the growing market demand for reliable and technologically advanced circuit cards.The new factory also signifies the company's commitment to local job creation and economic growth. By setting up the facility in [City, State], [Company Name] has created numerous employment opportunities, contributing to the growth of the local economy and fostering innovation within the region.As [Company Name] continues its expansion plans, the circuit card assembly factory empowers the company to further strengthen its market position and expand its reach globally. The facility is poised to drive innovation, provide exceptional products, and deliver unparalleled customer experiences.About [Company Name]:[Company Name] is a leading global provider of cutting-edge technology solutions for various industries. With a focus on innovation, quality, and customer satisfaction, the company is committed to delivering superior products and services that shape the future. [Company Name] operates in [number] countries and caters to a diverse range of clients, including multinational corporations and small businesses.

Latest Updates on China's Turnkey Box Build Services Revealed!

Title: China's Evolving Turnkey Box Build Industry Poised for GrowthIntroduction:China's turnkey box build industry has experienced tremendous growth in recent years, driven by the country's booming manufacturing sector. With a strong foundation in electronics manufacturing, China has become a global leader in providing efficient and cost-effective turnkey solutions. By harnessing its skilled labor force, advanced technology, and emphasis on high-quality outputs, the country aims to revolutionize the box build industry on a global scale.Paragraph 1:Box build refers to the complete assembly of electronic components into a finished product, ready for immediate use. This often involves the integration of printed circuit boards (PCBs), connecting cables, enclosures, and various other components. Traditionally, this process involved multiple suppliers and manufacturers working together to create a final product. However, turnkey box build solutions have emerged as a more streamlined and efficient alternative, offering end-to-end assembly and testing services.Paragraph 2:China, with its vast manufacturing capabilities, boasts numerous advantages that make it an ideal destination for turnkey box build projects. The country's extensive supply chain network ensures the availability of components at competitive prices. Additionally, strategic partnerships with component manufacturers allow for seamless integration within the assembly process. China's flexible manufacturing processes, combined with its skilled workforce, enable rapid and cost-effective production of high-quality electronic products.Paragraph 3:The increasing demand for turnkey box build solutions in various industries, such as automotive, telecommunications, consumer electronics, and healthcare, has propelled China's rise as the go-to destination for box build projects. This trend is fueled by the shifting dynamics in global supply chains, with many companies restructuring their operations to leverage China's efficient and reliable manufacturing capabilities.Paragraph 4:China has also invested heavily in research and development (R&D) activities to enhance its technological capabilities within the box build industry. Innovation centers and technology parks have been set up across the country to foster collaboration between industry leaders, manufacturers, and academic institutions. These initiatives aim to drive the adoption of advanced technologies such as automation, robotics, and artificial intelligence, further enhancing the efficiency and quality of turnkey box build processes.Paragraph 5:To ensure the highest standards and regulatory compliance, China has established stringent quality control and certification procedures. International standards such as ISO, UL, and RoHS are adhered to, ensuring that products manufactured in China meet global quality benchmarks. Additionally, the Chinese government continues to invest in training programs and certifications for its workforce to maintain the highest level of craftsmanship and expertise.Paragraph 6:China's turnkey box build industry has not been immune to the challenges posed by the global COVID-19 pandemic. However, the country's quick response in containing the virus and implementing effective safety measures has allowed the industry to quickly rebound. In fact, the pandemic has reinforced China's position as a reliable and resilient manufacturing hub, attracting companies seeking to diversify their supply chains and reduce dependency on a single region.Conclusion:China's turnkey box build industry is poised for continued growth and evolution, driven by its strong manufacturing capabilities, technological advancements, and emphasis on quality and efficiency. With the ongoing shift in global supply chains and the increased demand for reliable and streamlined assembly solutions, China remains at the forefront of the box build industry, paving the way for new opportunities and partnerships on a global scale.

Boost Your Electronics Manufacturing with High-Quality PCB Assembly Services

[Publication Name] – [Date]PCB Assembly Firm Enhances Production Capabilities to Meet Growing Demand[City, State] – With the increasing demand for advanced PCB assembly services, [PCB Assembly Firm] has expanded its production capabilities, allowing the company to better cater to the needs of its diverse clientele. As a leading provider of high-quality and reliable PCB assembly solutions, [PCB Assembly Firm] has established its position within the industry by combining cutting-edge technology, a skilled workforce, and a commitment to exceptional customer service.[PCB Assembly Firm] specializes in offering end-to-end PCB assembly services, including prototyping, component sourcing, assembly, testing, and quality control. Whether it's a small-scale project or a large-scale production run, the firm's state-of-the-art facility and experienced team ensure that each assembly meets the highest industry standards.Based in [City, State], [PCB Assembly Firm] has been serving a wide range of industries, including automotive, telecommunications, medical devices, consumer electronics, and more. The company's ability to adapt to evolving market trends and regulatory requirements has been instrumental in maintaining its strong clientele base and establishing itself as a trusted partner for businesses seeking reliable PCB assembly services.One of the primary reasons behind [PCB Assembly Firm]'s success is its continuous investment in advanced manufacturing equipment and technology. The firm recently upgraded its production facility, doubling its capacity and incorporating cutting-edge machinery. By doing so, [PCB Assembly Firm] ensures it remains at the forefront of technological advancements, guaranteeing the efficient and precise assembly of complex PCBs.The company's investment in new equipment has allowed it to meet the increased demand for high-density assemblies, incorporating smaller components while improving overall performance. As the industry continues to move towards miniaturization and improved functionality, [PCB Assembly Firm] is well-equipped to fulfill the evolving needs of its customers."We understand that our clients require not only high-quality PCB assembly services, but also timely deliveries," said [Spokesperson], the spokesperson for [PCB Assembly Firm]. "Our latest expansion enables us to maintain our commitment to quick turnaround times without compromising on quality. We take pride in our ability to fulfill our clients' assembly needs, no matter how complex."In addition to its investments in equipment, [PCB Assembly Firm] places significant importance on the expertise and skillset of its workforce. The company employs a team of highly trained technicians and engineers who are well-versed in the latest industry standards and best practices. This team is responsible for overseeing every step of the assembly process, ensuring that each product meets the stringent quality requirements expected by [PCB Assembly Firm]'s clients.Furthermore, [PCB Assembly Firm] is dedicated to unparalleled customer service. The company works closely with its clients, offering tailored solutions and project consultations to ensure that their specific requirements are met. By taking a collaborative approach, [PCB Assembly Firm] establishes long-term relationships with its clients, fostering a sense of trust and reliability.Looking ahead, [PCB Assembly Firm] aims to continue its growth trajectory by staying at the forefront of technological advancements in the PCB assembly industry. The company plans to invest further in research and development to better serve its clients' evolving needs and to expand its geographic reach.About [PCB Assembly Firm]:[PCB Assembly Firm] is a leading PCB assembly firm based in [City, State]. The company provides comprehensive PCB assembly services, utilizing cutting-edge technology, world-class equipment, and a skilled workforce to meet the diverse needs of its clientele. With a commitment to quality, efficiency, and customer satisfaction, [PCB Assembly Firm] has built a reputation as a trusted and reliable PCB assembly partner.Media Contact:[Person Name][Title][Company Name][Email Address][Phone Number]