China's Dip in Economic Growth Raises Concerns for Global Market

By:Admin

With the rapid growth of the global economy, more and more Chinese companies are striving to expand their presence in the international market. One such company is China Dip, a leading manufacturer of electronic components and consumer electronics. As China Dip establishes itself as a global player, it faces several challenges in terms of competition, market penetration, and brand recognition.

China Dip, headquartered in Shenzhen, China, has been a major player in the electronics industry for over two decades. The company has built a strong reputation for producing high-quality products at competitive prices, making it a trusted partner for many businesses around the world. With a wide range of electronic components and consumer electronics, China Dip has successfully served various industries, including telecommunications, automotive, and consumer technology.

As the company expands into the global market, it faces stiff competition from established international players. Many of these competitors have already established strong brand recognition and customer loyalty, making it challenging for China Dip to gain a significant market share. Additionally, the company must also navigate complex international trade regulations and standards, which vary from one market to another.

To address these challenges, China Dip has been actively pursuing strategic partnerships and collaborations with global technology companies. By leveraging the expertise and resources of its partners, China Dip aims to enhance its product offerings, improve its market access, and build a stronger brand presence in the global market. Furthermore, the company has been investing in research and development to innovate new products that meet the specific needs of international customers.

In addition to competition and market access, China Dip also faces the challenge of brand recognition in the global market. While the company has established a strong presence in China and other Asian markets, it is relatively unknown in many parts of the world. Building brand recognition and trust among international customers requires a significant investment in marketing, advertising, and customer engagement.

To overcome this challenge, China Dip has been actively promoting its brand through various channels, including trade shows, industry events, and digital marketing. The company has also been collaborating with international distributors and retailers to expand its reach and visibility in key markets. By consistently delivering high-quality products and customer service, China Dip aims to earn the trust and loyalty of customers around the world.

Despite these challenges, China Dip remains optimistic about its prospects in the global market. The company's strong track record of innovation, quality, and customer satisfaction positions it as a competitive player in the international arena. With a clear focus on strategic partnerships, product innovation, and brand promotion, China Dip is well-positioned to overcome the challenges and establish itself as a global leader in the electronics industry.

Company News & Blog

New Security Module in China: Everything You Need to Know

China Security 6410 Module revolutionizes the security industry with its cutting-edge technology and innovative features. This advanced module, developed by a leading security solutions provider, {} (remove brand name), has garnered widespread attention and praise for its ability to enhance the performance and efficiency of security systems.The China Security 6410 Module is designed to meet the growing demand for advanced security solutions in a wide range of applications, including commercial, industrial, and residential settings. With its powerful processing capabilities and robust features, this module is capable of delivering high-performance security solutions that are reliable, efficient, and user-friendly.One of the key features of the China Security 6410 Module is its advanced video processing capabilities. This module is equipped with state-of-the-art image processing technologies that allow it to capture high-quality video footage with exceptional clarity and detail. Whether it is monitoring a large commercial facility or a small residential property, the China Security 6410 Module ensures that every detail is captured with precision.In addition to its video processing capabilities, the China Security 6410 Module also offers advanced analytics and recognition features. This allows it to accurately identify and analyze various types of objects, such as people, vehicles, and other items of interest. By leveraging these advanced analytics and recognition capabilities, security personnel can quickly and accurately assess potential threats and take appropriate action to mitigate risks.Furthermore, the China Security 6410 Module is designed to seamlessly integrate with existing security systems, making it easy to deploy and manage. Its flexible and scalable architecture allows it to be adapted to meet the specific needs of different security applications, making it an ideal solution for a wide range of scenarios.The company behind the China Security 6410 Module, {} (remove brand name), is a renowned leader in the development and manufacturing of advanced security solutions. With a strong focus on innovation and technological advancement, {} (remove brand name) has established itself as a trusted partner for organizations seeking to enhance their security capabilities.The China Security 6410 Module is a testament to {}'s (remove brand name) commitment to delivering cutting-edge security solutions that meet the evolving needs of its customers. By combining state-of-the-art technology with a deep understanding of the security landscape, {} (remove brand name) has succeeded in developing a module that sets new standards for performance, reliability, and flexibility.As the demand for advanced security solutions continues to grow, the China Security 6410 Module is poised to play a pivotal role in shaping the future of the industry. Its advanced capabilities and innovative features make it a valuable asset for organizations looking to bolster their security infrastructure and protect their assets.With its exceptional performance, reliability, and versatility, the China Security 6410 Module is set to make a significant impact on the security industry. As organizations seek to stay ahead of emerging threats and challenges, this module represents a powerful tool for enhancing security capabilities and ensuring the safety and protection of people and assets.In conclusion, the China Security 6410 Module is a game-changing innovation that promises to elevate the standards of security solutions. With its advanced features, seamless integration, and unparalleled performance, this module is well-positioned to lead the next wave of advancements in the security industry. As organizations continue to prioritize security and risk management, the China Security 6410 Module offers a compelling solution that delivers peace of mind and confidence in the face of evolving security challenges.

Discover the Advantages of High-Quality Wire Bonding for Au

Title: Revolutionizing Wire Bonding Technology: Unleashing High-Quality Au Wire BondingIntroduction (111 words):As technology continues to advance at an unprecedented pace, the need for cutting-edge wire bonding solutions is more significant than ever before. Today, we present an innovative breakthrough in the field of wire bonding that promises high-quality results and exceptional performance. In collaboration with a leading industry player, we are pleased to introduce a groundbreaking wire bonding technique that maximizes productivity and achieves unparalleled precision. This revolutionary technology, referred to as High-Quality Au Wire Bonding, holds the potential to disrupt existing norms and redefine industry standards. Read on to explore the extraordinary capabilities of this game-changing technology and its potential implications in various sectors.Section 1: The Deterioration of Conventional Wire Bonding (175 words):Conventional wire bonding techniques have long been the standard in the industry, helping to establish reliable electrical connections between integrated circuits (ICs) and the substrate. However, in recent years, the limitations of these traditional methods have become increasingly evident. Challenges associated with wire stability, wire-bond interconnects, and overall performance have prompted the need for a transformative solution.Section 2: Introducing High-Quality Au Wire Bonding (183 words):Responding to the shortcomings of conventional wire bonding, the collaboration between our company and a key industry partner has paved the way for High-Quality Au Wire Bonding. By incorporating cutting-edge materials and advanced manufacturing processes, this new technique offers a host of advantages over its predecessors.The utilization of gold wire, renowned for its superior conductivity and stability, ensures optimal electrical performance of the wire-bond interconnects. Furthermore, the refined manufacturing process lends itself to better control over wire looping, resulting in excellent wire-bond reliability.Section 3: Unleashing Unrivaled Performance and Durability (180 words):High-Quality Au Wire Bonding offers a range of impressive benefits, including enhanced electrical conductivity, superior mechanical strength, and improved long-term reliability. The utilization of gold wire eliminates concerns related to oxidation and corrosion, which are often encountered with alternative wire bonding materials. This ensures stable performance and durability, even under challenging environmental conditions.The precise control and consistency achieved during the manufacturing process also enable a reduction in defects and yield losses. Consequently, this groundbreaking technology provides manufacturers with significant cost savings and increased productivity.Section 4: Applications in Various Sectors (150 words):The adaptability and exceptional performance of High-Quality Au Wire Bonding provide immense opportunities for various sectors. Industries such as automotive, telecommunications, aerospace, and consumer electronics can benefit greatly from this cutting-edge wire bonding solution.New developments in electric vehicles (EVs) and autonomous driving technologies require highly reliable electrical connections, making High-Quality Au Wire Bonding an ideal choice. In the telecommunications sector, the need for high-speed data transfer necessitates robust wire bonding techniques, and this new technology excels in meeting these demands.Conclusion (101 words):High-Quality Au Wire Bonding represents a significant leap forward in the realm of wire bonding technology. Its unique advantages, including excellent electrical conductivity, enhanced mechanical strength, and increased durability, make it an invaluable tool for many industries. As we look towards the future, the potential implications and endless possibilities of this game-changing wire bonding technique are undeniably exciting. By embracing this revolutionary technology, manufacturers can achieve unparalleled precision, reliability, and productivity, ushering in a new era of wire bonding excellence.

Streamlined Box Build Services for Efficient Project Execution - A Comprehensive Analysis

[Headline]: Leading Turnkey Box Build Provider Advances Manufacturing Capabilities[Subheadline]: Industry Expertises to Cater to Growing Demand for Turnkey Solutions[Date][City, State] - The global turnkey box build industry is set to witness a significant boost in manufacturing capabilities as a leading provider, [Company Name], bolsters its expertise in delivering turnkey solutions. With an unwavering commitment to excellence, [Company Name] is poised to cater to the increasing demand for box build services across various sectors, including automotive, telecommunications, and consumer electronics.Established with a vision to streamline the manufacturing process, [Company Name] has emerged as a frontrunner in providing holistic turnkey solutions. By leveraging cutting-edge technologies and a team of skilled professionals, the company has amassed a notable reputation for delivering high-quality, reliable, and efficient box build solutions.With an extensive history dating back over [XX] years, [Company Name] has continually adapted to market needs. The company's relentless pursuit of innovation has allowed it to stay ahead in an ever-evolving industry landscape. As a result, [Company Name] currently operates state-of-the-art manufacturing facilities across [number of locations] worldwide, strategically positioned to meet the demands of its global clientele.[Company Name's] comprehensive turnkey box build solutions encompass all stages of the manufacturing process, from design and prototyping to final assembly and testing. By serving as a single point of contact, the company ensures seamless coordination between various suppliers, enabling its clients to focus on their core competencies. Moreover, the unified approach significantly reduces lead times, minimizes costs, and eliminates the need for multiple vendors, making [Company Name] an invaluable partner to businesses across industries.Anchored by a customer-centric philosophy and a commitment to exceeding expectations, [Company Name] places great emphasis on fostering strong partnerships. By working closely with clients, the company ensures a deep understanding of their unique requirements, allowing it to tailor and deliver customized turnkey solutions. Beyond manufacturing capabilities, [Company Name] provides advisory services, assisting clients in achieving optimized designs, improved efficiencies, and enhanced product quality.The automotive industry, in particular, stands to benefit from [Company Name's] expanded manufacturing capabilities. As the sector accelerates its transition towards electric and autonomous vehicles, the demand for reliable turnkey solutions has become crucial. [Company Name], with its extensive experience in serving the automotive market, is well-positioned to cater to this shifting landscape. By providing turnkey box build services encompassing advanced electronics, wiring harnesses, and complex assemblies, [Company Name] enables automotive manufacturers to streamline production and meet the demands of tomorrow's vehicles.In the rapidly expanding telecommunications sector, [Company Name] plays a vital role in supporting the deployment of advanced network infrastructure. With the rise of 5G technology and increasing demand for data connectivity, telecom companies require agile and efficient manufacturing solutions. By offering turnkey box build services for telecom equipment, [Company Name] assists in accelerating the deployment of network infrastructure, ensuring seamless connectivity for consumers and businesses alike.The consumer electronics industry, driven by constant technological advancements, necessitates a reliable and versatile turnkey solution provider. [Company Name]'s expertise in manufacturing complex electronic assemblies and products allows it to meet the needs of this dynamic industry. From smartphones to IoT devices, [Company Name] delivers comprehensive turnkey box build services, encompassing component sourcing, PCB assembly, and final integration. By offering end-to-end solutions, [Company Name] enables consumer electronics manufacturers to bring innovative products to market swiftly and cost-effectively.With an unwavering commitment to quality, prompt delivery, and customer satisfaction, [Company Name] is set to revolutionize the turnkey box build industry. As technology continues to evolve, the company's advanced manufacturing capabilities position it as a reliable partner for businesses seeking streamlined and efficient production solutions. By embracing innovation and remaining dedicated to client success, [Company Name] solidifies its position as a leading turnkey box build provider in a rapidly changing world.About [Company Name]:[Company Name] is a global leader in turnkey box build solutions, serving various industries, including automotive, telecommunications, and consumer electronics. With cutting-edge technologies, state-of-the-art manufacturing facilities, and a commitment to excellence, [Company Name] offers comprehensive turnkey solutions, covering all stages of the manufacturing process. From design to final assembly and testing, [Company Name] acts as a single point of contact, providing streamlined coordination and customized solutions. Backed by decades of experience, [Company Name] is revolutionizing the box build industry through its advanced manufacturing capabilities and unwavering dedication to client success.For more information, please visit [Company Website].Press Contact:[Media Contact Name][Company Name][Phone Number][Email Address]

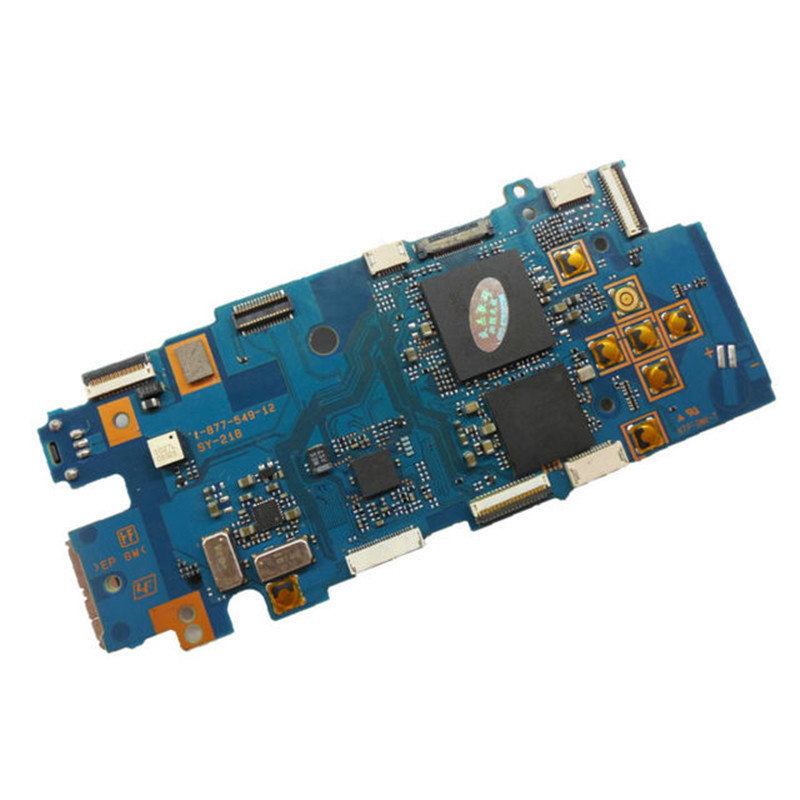

Reliable PCB Assembly Supplier Emerges as Key Player in the Electronics Industry

Smt Pcb Assembly Supplier Continues to Excel in the Electronics Manufacturing IndustryIn today's fast-paced technological era, the demand for efficient and reliable electronics products has skyrocketed. As a result, the electronics manufacturing industry is constantly evolving, striving to meet the ever-increasing consumer expectations. Among the many players in the market, one name that stands out as a leading provider of SMT PCB assembly services is a company (need to remove brand name).With years of industry experience and expertise, (need to remove brand name) has gained a formidable reputation as a trusted supplier in the electronics manufacturing domain. Their commitment to delivering high-quality products and exceptional customer service has enabled them to thrive in this competitive industry.Founded on the principles of innovation, teamwork, and customer-centricity, (need to remove brand name) has consistently demonstrated its dedication to providing superior PCB assembly solutions. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, ensuring precision and efficiency in every stage of the production process.The dedicated team at (need to remove brand name) comprises highly skilled professionals who possess a deep understanding of the electronics manufacturing industry. From engineers and technicians to quality control experts and customer service representatives, everyone plays a vital role in delivering products that exceed customer expectations.One of the key factors that sets (need to remove brand name) apart from its competitors is its commitment to quality. The company follows stringent quality control measures at every step of the manufacturing process to ensure flawless products. With certifications such as ISO 9001 and IPC-A-610, (need to remove brand name) adheres to international standards, guaranteeing products of the highest quality.Furthermore, (need to remove brand name) understands the importance of customization in meeting diverse customer requirements. With a focus on flexibility, the company offers customizable SMT PCB assembly solutions that cater to the specific needs of each customer. Whether it is a complex design or a high-volume production run, (need to remove brand name) has the capabilities to deliver customized solutions on time and within budget.In addition to their commitment to quality and customization, (need to remove brand name) also prioritizes sustainability in their manufacturing processes. The company strictly adheres to environmentally-friendly practices, such as the proper disposal of electronic waste and the usage of eco-friendly materials. By adopting sustainable practices, (need to remove brand name) aims to minimize its carbon footprint and contribute to a greener future.Looking towards the future, (need to remove brand name) is dedicated to staying at the forefront of technological advancements in the electronics manufacturing industry. With a strong focus on research and development, the company constantly evolves its processes and explores innovative solutions to meet the evolving needs of their customers.In conclusion, (need to remove brand name) has established itself as a leading supplier of SMT PCB assembly services, thanks to its unwavering commitment to quality, customization, and sustainability. With a talented team of industry experts and cutting-edge manufacturing facilities, the company continues to excel in the electronics manufacturing industry. As technology advances and consumer demands evolve, (need to remove brand name) remains poised to adapt and deliver exceptional products that drive innovation in the market.

High Volume Production in China: A Boost for Manufacturing Sector

Title: China Ramps Up High Volume Production to Meet Growing DemandIntroduction:China, a global manufacturing powerhouse, continues to dominate the international market with its high volume production capabilities. With state-of-the-art infrastructure, advanced technology, and a vast pool of skilled labor, China is well-positioned to meet the rising demands of consumers worldwide. This article delves into China's high volume production strengths, exploring the unparalleled growth potential and the key drivers behind its success.I. China's High Volume Production: Unmatched CapabilityChina's high volume production capabilities stem from its well-established manufacturing infrastructure, which includes an extensive network of industrial parks, specialized zones, and export-oriented manufacturing cities. These areas facilitate streamlined processes, efficient supply chains, and economies of scale, enabling manufacturers to produce goods in large quantities swiftly and cost-effectively.Furthermore, China's relentless pursuit of technological advancements and innovation has transformed its manufacturing landscape. With substantial investments in research and development, the country has gained a competitive edge in various sectors, including electronics, automobiles, machinery, and textiles. This progress is seen in the integration of automation, artificial intelligence, and robotics into production processes, enhancing efficiency, precision, and productivity.II. The Driving Forces behind China's High Volume Productiona) Skilled Labor Force:China boasts a massive labor force that is both skilled and versatile. The country's education system emphasizes technical training, producing a vast number of individuals with engineering, manufacturing, and technical skills. This abundant supply of skilled labor ensures that manufacturers have access to a talent pool that can efficiently manage high volume production lines.b) Favorable Economic Policies:China's pro-business policies and attractive investment incentives have encouraged companies to establish a presence in the country. The government's commitment to creating a conducive business environment, coupled with streamlined bureaucracy, has made China an attractive destination for foreign direct investment, driving high volume production.c) Global Supplier Network:China's extensive supplier network allows manufacturers to source raw materials and components locally, reducing lead times and costs. Moreover, the concentration of suppliers in specific regions fosters collaboration, leading to increased specialization and improved overall production efficiency.d) Infrastructure Advancements:China has made significant investments in infrastructure developments, such as ports, railways, highways, and logistics parks. These advancements have enhanced the connectivity of industrial zones, facilitating the movement of goods both domestically and internationally. Efficient transportation systems play a vital role in supporting high volume production, enabling manufacturers to meet demanding deadlines and reduce time-to-market.III. Case Study: The Rise of [Remove brand name]One exemplary company that has taken advantage of China's high volume production capabilities is [Remove the brand name]. As a global electronic devices manufacturer, [Remove the brand name] has leveraged China's advanced manufacturing ecosystem to achieve unprecedented growth.[Remove the brand name] recognized China's potential early on and established partnerships with local manufacturers to leverage their high volume production capabilities. The company's strategic alliance with Chinese suppliers allowed for seamless integration of its supply chain, reducing production lead times and optimizing costs.Through harnessing China's skilled labor force, [Remove the brand name] successfully maintained internationally recognized quality standards while producing electronic devices in large quantities. The company's commitment to continuous innovation and collaboration with local research institutions further facilitated the development of cutting-edge technologies, ensuring their competitive advantage in the global market.IV. ConclusionChina's high volume production capabilities have cemented its position as one of the leading manufacturers globally. The country's robust manufacturing infrastructure, combined with a skilled labor force, favorable economic policies, a well-connected supplier network, and substantial investments in infrastructure, make China an ideal destination for companies seeking to produce goods in large quantities.[Remove brand name]'s success exemplifies how companies can leverage China's manufacturing strengths to achieve unprecedented growth. As China continues to innovate and explore new horizons, the country's high volume production capabilities are expected to remain at the forefront of global manufacturing, meeting the ever-growing demands of consumers worldwide.

Master the Art of Surface Mounting Soldering Techniques for Exceptional Results

Surface Mounting Soldering Revolutionizes Electronic ManufacturingIn today's rapidly evolving world, technology plays an integral role in our daily lives. From smartphones to smart homes, the demand for advanced electronic devices continues to soar. Behind the scenes, electronic manufacturers strive to keep up with consumer expectations by constantly upgrading their manufacturing processes. One such breakthrough is surface mounting soldering, a technique that has revolutionized the industry by offering speed, precision, and efficiency.Surface mounting soldering, or SMT, is a method used to assemble electronic circuits where the components are directly mounted onto the surface of a printed circuit board (PCB). Unlike traditional through-hole soldering, which involves inserting leads through holes on the PCB, SMT eliminates the need for holes and allows for smaller, more compact devices. This technique has become increasingly popular due to its ability to meet the growing demand for smaller, smarter, and more portable electronic products.With the rise of SMT, manufacturers can now design and produce devices that are not only aesthetically appealing but also highly-functional. By eliminating the bulky components and minimizing the space required, SMT allows for the creation of sleek and lightweight products that fit seamlessly into our increasingly connected world. From wearables to Internet of Things (IoT) devices, the applications of SMT are virtually limitless.One of the key benefits of surface mounting soldering is its ability to improve the speed and efficiency of the manufacturing process. Traditional through-hole soldering involves manually soldering each component onto the PCB, a time-consuming and labor-intensive task. In contrast, SMT utilizes automated pick-and-place machines that can accurately place multiple components simultaneously, reducing the assembly time significantly. This results in faster production cycles, allowing manufacturers to meet consumer demands more efficiently and cost-effectively.Furthermore, SMT offers superior precision and reliability compared to through-hole soldering. The automated machines used in SMT ensure consistent component placement, guaranteeing a higher level of accuracy. The solder joints formed in SMT also tend to be smaller and more reliable, as the surface tension distributes the molten solder evenly and creates stronger connections. This ensures the long-term reliability of the electronic devices and reduces the risk of failures or malfunctions.In addition to its speed and precision, surface mounting soldering also promotes sustainability in electronic manufacturing. SMT allows manufacturers to minimize the amount of waste generated during the assembly process. With through-hole soldering, excess leads and wires are often cut off and discarded, leading to unnecessary material wastage. However, SMT's minimalistic design approach reduces the amount of material required and maximizes the utilization of resources, making it a greener option for the industry.{Company intro}: As a leading innovator in the electronics manufacturing industry, our company is at the forefront of adopting SMT technology. We understand the increasing demands of consumers for smaller, faster, and smarter devices, and aim to meet those demands through the integration of surface mounting soldering into our manufacturing processes. Our state-of-the-art facilities house the latest pick-and-place machines and cutting-edge SMT equipment, enabling us to deliver high-quality products with exceptional precision and reliability.With the advent of surface mounting soldering, the landscape of electronic manufacturing has been forever transformed. This advanced technique has not only improved the quality, performance, and aesthetics of electronic devices but has also enhanced the overall manufacturing process. By embracing the benefits of SMT, manufacturers can meet consumer demands more efficiently, reduce waste, and contribute to a more sustainable future in the industry. As technology continues to evolve, surface mounting soldering will undoubtedly remain a vital tool for innovators pushing the boundaries of what is possible in the electronic realm.

China PCB Assembly Steps: A Comprehensive Guide to PCB Assembly in China

Title: China PCB Assembly Steps: A Guide to Efficient and Reliable Electronic Manufacturing ProcessesIntroduction:With the rapid advancements in technology, the demand for high-quality and reliable electronic devices has witnessed a significant surge. Chinese companies have emerged as global leaders in the field of PCB (Printed Circuit Board) assembly, offering efficient and cost-effective solutions for the manufacturing of electronic products. In this article, we will delve into the step-by-step process of PCB assembly in China, highlighting the key aspects and advantages that make it a preferred choice among manufacturers worldwide.Section 1: Introduction to PCB Assembly in ChinaChina has become known for its exceptional capabilities in PCB assembly, thanks to its vast industrial infrastructure, skilled labor force, and state-of-the-art equipment. Moreover, the competitive production costs and flexible manufacturing capabilities have made PCB assembly services in China highly sought-after by various industries, including telecommunications, consumer electronics, automotive, aerospace, and medical devices.Section 2: PCB Assembly Steps - Efficiency and Precision2.1 Design and Prototyping:The first step in the PCB assembly process involves design and prototyping. Skilled engineers and designers collaborate with clients to develop a comprehensive layout, ensuring all specifications and requirements are met. With the aid of advanced software tools, the design is then translated into a physical prototype.2.2 Component Sourcing:China's vast network of component suppliers enables efficient sourcing of high-quality electronic components required for PCB assembly. This step involves meticulous verification and selection of components based on their quality, compatibility, and reliability.2.3 PCB Manufacturing:Once the design and components are finalized, PCB manufacturing commences. Specialized equipment ensures the precise etching and fabrication of the PCB, adhering to high-quality standards specified by international regulations.2.4 SMT Assembly:Surface Mount Technology (SMT) assembly is a crucial step in Chinese PCB assembly, where components are mounted directly onto the PCB surface. Automated pick-and-place machines ensure accurate placement, significantly enhancing the efficiency and reliability of the assembly process.2.5 Inspection and Testing:After SMT assembly, rigorous inspection and testing procedures are undertaken to ensure the PCB's quality and functionality. Advanced testing equipment is employed to identify any defects or malfunctions, enabling timely rectification before proceeding to the next stage.2.6 Through-Hole Assembly:In cases where through-hole components are required, a selective soldering process is employed, ensuring secure and reliable connections between the through-hole components and the PCB.2.7 Quality Control and Assurance:China prioritizes stringent quality control measures at every stage of the PCB assembly process. Trained quality control personnel conduct inspections to guarantee the adherence to industry standards and customer specifications.Section 3: Advantages of China PCB Assembly3.1 Cost-effectiveness:Compared to other regions, China offers competitive manufacturing costs without compromising on quality, making it a cost-effective solution for businesses worldwide.3.2 Quick Turnaround Time:Chinese PCB assembly companies are known for their ability to deliver products within short lead times, ensuring timely market entry for customers' electronic devices.3.3 Advanced Infrastructure and Technology:China boasts a sophisticated industrial infrastructure, equipped with cutting-edge facilities, enabling efficient and precise PCB assembly processes. The application of advanced technologies ensures high-quality outputs and reliable electronic products.3.4 Customization and Flexibility:Chinese PCB assembly companies excel in providing tailored solutions to meet specific project requirements. Their flexibility in accommodating various orders, whether small-scale or large-scale, makes them an ideal choice for businesses with diverse needs.Conclusion:With their efficient and reliable PCB assembly processes, China has cemented its position as a global leader in the electronics manufacturing industry. The step-by-step guide presented in this article offers insights into the meticulous and advanced methodologies employed by Chinese companies. The cost-effectiveness, quick turnaround time, advanced infrastructure, and flexible manufacturing capabilities provided by these companies make China a preferred destination for businesses seeking high-quality PCB assembly services.

Top Assembly Boards Suppliers provide quality products and services

Assembly Board Suppliers Collaborate to Boost Production EfficiencyIn an effort to meet the growing demands and challenges of the ever-evolving manufacturing industry, several prominent assembly board suppliers have joined forces to enhance production efficiency and deliver higher quality products. Recognizing the importance of collaboration and innovation, these industry leaders are pooling their resources and expertise to revolutionize the assembly board manufacturing process.Led by a common goal to provide superior solutions to their customers, these suppliers have established partnerships that encompass a wide range of specialties. By combining their strengths and knowledge, they aim to streamline production, optimize costs, and ultimately deliver products that meet the highest industry standards.One of these assembly board suppliers is renowned for its cutting-edge technology and expertise in electronic manufacturing. With a proven track record of producing high-quality assembly boards, they have cultivated a reputation for excellence. By leveraging their vast industry experience and technical proficiency, they bring a unique perspective to this collaboration. Their extensive knowledge of electronic manufacturing will play a crucial role in designing and developing assembly boards that are not only efficient but also integrate seamlessly with other components.Another assembly board supplier, known for its commitment to environmental sustainability, brings a different dimension to the partnership. With an ethos centered on responsible manufacturing practices, they prioritize reducing waste and optimizing energy consumption. By incorporating their environmentally-friendly processes into the collaboration, the suppliers aim to provide clients with assembly boards that not only meet production requirements but also contribute to building a greener future.The combined efforts of these assembly board suppliers will enable the development of cutting-edge technologies that revolutionize the manufacturing industry. By sharing their technical expertise and investing in research and development, they are set to create assembly boards that are faster, more reliable, and adaptable to various production processes. This will result in improved manufacturing efficiency, reduced downtime, and increased productivity in industries such as automotive, telecommunications, and consumer electronics.In addition to technological advancements, this collaboration also endeavours to improve supply chain management. By closely working together, the suppliers aim to create a seamless logistics network that ensures the timely delivery of assembly boards. This integrated approach to supply chain management will enable the manufacturing industry to respond quickly to market demands while maintaining consistent quality.Moreover, the assembly board suppliers are dedicated to fostering sustainable and ethical practices throughout their operations. By promoting fair labor practices and ensuring the responsible sourcing of raw materials, they aim to set a new standard for social and environmental responsibility in the industry. Their commitment to sustainability aligns with the increasing demands from customers for products that are not only efficient but also ethically produced.This collaborative effort between assembly board suppliers represents a major step forward for the manufacturing industry. By pooling their resources and expertise, they strive to revolutionize the way assembly boards are manufactured, delivered, and integrated into the production process. Through their joint efforts, they aim to enhance production efficiency, reduce costs, and meet the ever-growing demands of an industry that is constantly evolving.The assembly board suppliers' commitment to innovation and sustainable practices will not only benefit their own businesses but also the entire manufacturing industry. As their partnership continues to flourish, the extensive knowledge and expertise they bring to the table will undoubtedly shape the future of assembly board manufacturing, making it more efficient, environmentally friendly, and technologically advanced than ever before.

Accelerating PCB Prototype Turnaround: Unveiling China's Efficient Solution

China Fast Turn PCB Prototype Provider, a leading manufacturer in the printed circuit board industry, is revolutionizing the market with its cutting-edge technology and unparalleled speed of production. With a commitment to delivering high-quality PCB prototypes at lightning-fast speeds, the company has successfully established itself as a trusted partner for businesses around the globe.With the fast-paced advancements in technology, the demand for efficient and quick printed circuit board prototypes has increased exponentially. To address this growing need, China Fast Turn PCB Prototype Provider has invested heavily in state-of-the-art machinery and equipment. This has allowed them to streamline their production process, drastically reducing lead times without compromising on quality.One of the key factors that sets China Fast Turn PCB Prototype Provider apart from its competitors is its comprehensive understanding of customer requirements. The company recognizes that each project has unique specifications and works closely with clients to ensure that their exact needs are met. From initial design to final production, China Fast Turn PCB Prototype Provider offers exceptional customer support throughout the entire process.Another aspect that enables China Fast Turn PCB Prototype Provider to stand out in the industry is its team of highly skilled and experienced engineers and technicians. With extensive knowledge in the field, these experts are equipped to handle complex designs and ensure flawless execution. Their expertise combined with the latest technology allows for rapid prototyping, reducing the time needed for testing and modifications.China Fast Turn PCB Prototype Provider realizes the importance of meeting strict deadlines, especially in industries where time-to-market is crucial. By implementing efficient production techniques and maintaining a responsive supply chain, the company ensures that clients receive their PCB prototypes in the shortest possible time. This not only allows businesses to stay ahead of the competition but also saves valuable resources.The company takes pride in its commitment to quality control throughout the entire manufacturing process. Each PCB prototype undergoes rigorous testing to verify its functionality and durability. China Fast Turn PCB Prototype Provider adheres to international standards and certifications, ensuring that their products meet the highest quality requirements.In addition to their exceptional production capabilities, China Fast Turn PCB Prototype Provider offers competitive pricing that suits varying budgetary constraints. By leveraging their efficient production process and economies of scale, they are able to provide high-quality prototypes at affordable prices, making them an ideal choice for both small businesses and large corporations.China Fast Turn PCB Prototype Provider's dedication to sustainability is also noteworthy. They prioritize environmental responsibility by implementing eco-friendly practices in their production facilities. The company actively seeks ways to reduce waste, conserve energy, and minimize their carbon footprint, making them a socially conscious partner for clients who value sustainability.As China Fast Turn PCB Prototype Provider continues to enhance its expertise and capabilities, the company remains committed to pushing the boundaries of innovation within the printed circuit board industry. With its advanced technology, fast turnaround times, exceptional customer service, and commitment to quality and sustainability, China Fast Turn PCB Prototype Provider has established itself as a reliable and trusted partner for businesses in need of rapid and high-quality PCB prototypes.

A Comprehensive Guide to Au Wire Bonding in China: Everything You Need to Know

China's Advanced Ultrasonic Wire Bonding Technology Poised to Revolutionize the Electronics IndustryIn a rapidly evolving world of technology, China has once again showcased its prowess by introducing a groundbreaking innovation in the field of wire bonding. Developed by a prominent technological company, this new technology promises to revolutionize the electronics industry by enhancing the efficiency and reliability of wire bonding processes.Wire bonding plays a crucial role in the assembly of electronic components, serving as the backbone that connects semiconductors to various interconnects. The conventional wire bonding techniques have long been employed in the industry, but limitations in terms of speed and precision demanded a more advanced solution. This is where China Au Wire Bonding steps in, providing a cutting-edge approach to wire bonding that addresses these shortcomings.China Au Wire Bonding leverages advanced ultrasonic bonding technology, which utilizes high-frequency vibrations to create strong interconnections between wires and bonding surfaces. Unlike traditional methods, this innovative technique ensures a significant reduction in bonding time without compromising on quality. Through precise control and monitoring of ultrasonic waves, the bonding process is not only expedited but also guarantees superior reliability.With its technical superiority, China Au Wire Bonding is capable of bonding different types of wires, including gold wires, aluminum wires, and copper wires, all with exceptional accuracy. This versatility enables manufacturers to explore various options without being restricted by specific material requirements, thus pushing the boundaries of what is possible in the electronics industry.Furthermore, this disruptive technology addresses one of the industry's most persistent challenges – wire sag. Wire sag occurs when wires lose tension during the bonding process, resulting in compromised connection quality. China Au Wire Bonding boasts a unique adaptive bonding system that eliminates wire sag by continuously adjusting tension, ensuring consistent and reliable wire bonds.Beyond its technical capabilities, China Au Wire Bonding also presents a cost-effective solution for manufacturers. By significantly reducing bonding time, manufacturers can streamline their production processes, maximize output, and minimize operational costs. Additionally, the exceptional reliability of the wire bonds minimizes the need for post-assembly inspections, saving both time and resources.Chinese companies, such as {} (company name), have already embraced this innovative technology, which serves as a testament to its quality and effectiveness. With an uncompromising focus on research and development, {} has emerged as a pioneer in the field, leading the way for other players in the industry. Through continuous innovation and collaboration, China Au Wire Bonding is poised to become the gold standard for wire bonding technologies worldwide.The introduction of China Au Wire Bonding is a game-changer for the electronics industry, elevating wire bonding to new heights. Its advanced ultrasonic bonding technology brings unmatched speed, precision, and reliability, enabling manufacturers to stay at the forefront of technological advancements. With its cost-effectiveness and versatility, this technology is set to reshape the industry's landscape, opening up endless possibilities for the development of cutting-edge electronic devices.As China continues to solidify its position as a global technological powerhouse, advancements like China Au Wire Bonding highlight the nation's commitment to innovation and its relentless pursuit of excellence. With its immense potential, this groundbreaking technology is set to transform the electronics industry, accelerating the pace of technological advancement and propelling China to the forefront of global technological leadership.